AirRepair Leads the Way

AirRepair® Leak Repair solves a cracking problem

Cracked Lead-Sheathed Cable in Manhole

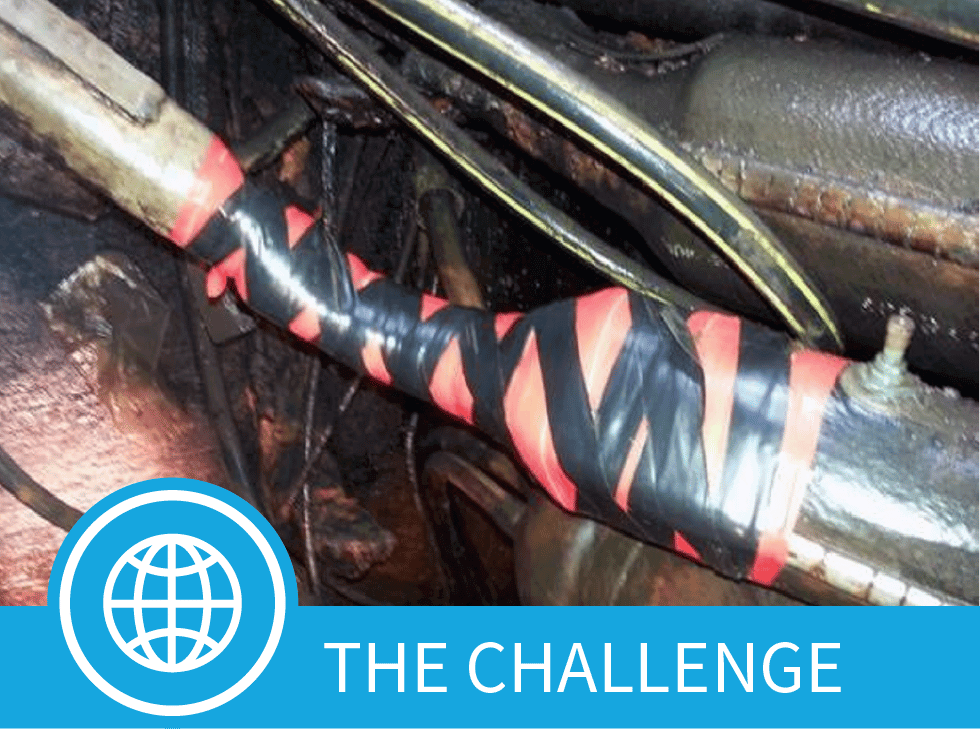

Chris Godfry, employee of a British telecommunications company, was experiencing problems where lead -sheathed paper-insulated E/side cables were cracked within the duct mouth. This caused high airflow and created an opportunity for water ingress.

It was believed the cables were inadvertently damaged through increased manual activity in underground networks when installing fiber. Footprints were observed on the cables. When these cables fail, the average cost of replacement is £5,000 (US $5,917).

Creating a Durable Repair with AirRepair

Previous attempts to repair the hole were made with tape and putty. Unfortunately, the tape did not provide stability when the cable was moved, allowing the cracks to continue to propagate, and the compression tape leaked.

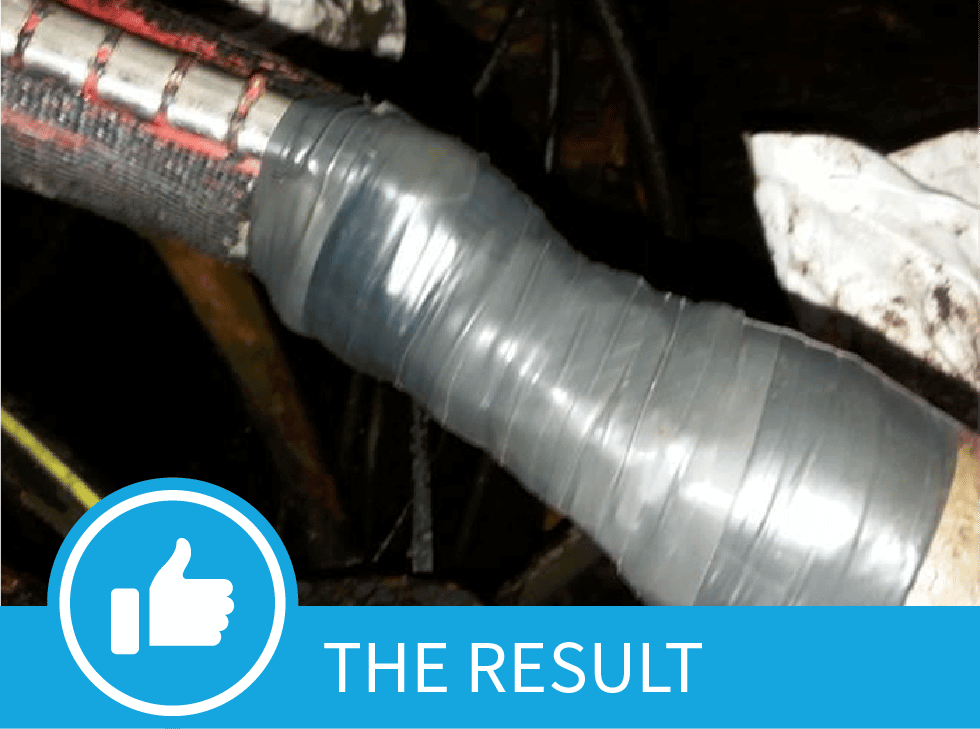

Godfry felt AirRepair Sealant could be an excellent solution for in-field repair. It is supplied in single, user- friendly, ready-to-use packs, and can be applied to pressurized cable so there is no service disruption. The no-sag material requires no special application tools.

A Long-Lasting, Flexible, Cost-Effective Solution

Within 10-15 minutes, the AirRepair seal stopped the air leaks and limited further cracking. This repair has better results and performance than tape and putty used in the past. The high-strength AirRepair seal lends stability to the cable so it can withstand vibration and movement—even footsteps.

AirRepair cures to a durable material that flexes and moves with the cable. The seal holds 10 psi (690mb) and is resistant to water, salt, oils, and other manhole contaminants.

Each pack contains enough material to seal one leak and can be spread along seams, around the body of the cable, or in the crotch joint of a splice. AirRepair seals leaks at a fraction of the cost of cable replacement, leading as an economical, high-performance solution for infrastructure maintenance.