Why DIY Store Foams Fail to Seal Conduits

One-part aerosol foams are cheap and easy to use, but learn why their use as a duct sealant can be problematic.

One-part, “gap and crack” foams used in the building trades are sometimes used to seal electrical and telecommunications conduits. These “canned foam” products are cheap and common. They appear to comply with industry codes mandating that conduits be sealed. Unfortunately, these seemingly ideal sealants too often fall short of expectations, failing to seal. This failure far outweighs any perceived convenience or cost savings over high-performance, engineered sealing solutions. This article reviews one-part aerosol foams and analyzes specifically why their use as a duct sealant can be problematic.

One-Part vs. Two-Part Aerosol Foam

”One-part” aerosols require moisture from the air to fully react. When dispensed from the can it reacts with moisture in the air to harden. This is effective when such foams are applied to wood materials. Wood is an excellent source of moisture for curing. “Two-part” aerosols contain two chambers, one with resin, and one with a curing agent. The two materials are mixed when dispensed, triggering the curing process—the presence of moist air is not required. Everything needed to make the functioning foam is contained in the two parts. Because nothing is required from the environment, these foams tend to be much more consistent and less affected by changes in that environment. They are also more appropriate for use with a wide range of materials.

| Related Content: Is Meeting a Standard Enough?—An Examination of Duct Sealing Code Compliance. |

Is There a Problem, Officer?

One-part aerosol foam is an efficient technology with many excellent uses. It seals gaps and cracks and works well to reduce drafts, moisture, dust, insects, and noise. Many commercially available canned foams are UL approved.

One-part aerosol foam is not, however, an excellent conduit sealant. It is important to note that a UL mark does not make a product suitable for a purpose other than the one for which it’s designed or marketed. In the case of one-part canned foams, the UL mark is generally not for sealing conduit entrances containing electrical or communications cables. Despite this, one-part canned foam is often used as a conduit sealant. Specifiers and engineers should understand that this is problematic for reliable cable installations because one-part foam fails as a long-term sealant solution. It may work well to reduce drafts, but under pressure it is not considered airtight or watertight.

The Mechanisms of Seal Failure

The first problem is that, as mentioned earlier, one-part foams require moist air to cure. That is hard to come by in the tight confines of a conduit. As an installer sprays a wad of one-part foam into a conduit, both ends of the wad are exposed to air. They expand and cure as expected, and at least visually to the installer, everything looks copasetic. However, the middle section of the wad is not exposed to air. It is blocked from the air by the encompassing inner walls of the conduit and the slowly cured butt ends of the wad itself. Laboratory research shows that in conduit, one-part foams simply don’t cure to a depth of much more than one inch (2.5 cm) at the ends, while the center of the “seal” can remain uncured indefinitely.

Jelly-filled donuts are a good thing; jelly-filled duct seals, not so much. The real-world consequence is that the moment either end of the cured seal is breached, the uncured inner portion is easily swept away by even minute levels of air or water pressure, thus allowing access to water, gas, dirt, insects, snakes, rodents, fire ants, etc. In essence, the uncured material is a complete waste of money. Instead of, say, an intended 6-inch (15 cm) -long seal, the final cured product results, at best, in two far weaker 1-inch (2.5-cm) seals.

The second problem is the adhesive nature of the one-part foam. The one-part foam is built to adhere to wood surfaces commonly used in construction. The PVC, steel, fiberglass, or HDPE in today’s conduits may present an adhesive challenge that the one-part foam cannot meet. Adhesion failure leads directly to gas and water leaks. It may take time for water (or gas) to wind its way through these failures, but lab research and field experience prove that it does. The higher the water head or air pressure, the faster the failure. Two-part foams can be formulated to actively adhere to conduit materials, eliminating this type of failure. One-part aerosol foams used as conduit seals are too often temporary at best.

Measuring Performance

How much water head will a one-part aerosol foam conduit seal hold compared to a two-part, closed-cell foam? How many psi of gas pressure will it resist comparatively? The answer to these two very important questions, unfortunately, is not much.

| Related Content: Duct Seals Prevent Ruinous Water Damage. |

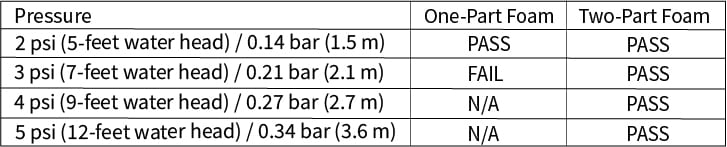

The water blocking capability of one-part and two-part aerosol foams was quantified using a hydrostatic test. In this test, a 2” clear PVC conduit was filled with a 6” plug of each material and allowed to cure for 24 hours. The seals were then tested at the pressures below for water tightness.

The one-part foam demonstrates dramatically inferior sealing performance. This should be of significant concern to engineers committed to the installation of robust cable systems.

Another issue is the misperception that such foams are fire retardant because they’re described as fire or smoke blocks. They are tested according to UL 723 for fire and smoke generation. This classification does not indicate fire retardancy and there are no pass/fail criteria for this listing. This fire/smoke property is often a selling point for such products. To quantify the fire properties, several one-part foams were tested to UL 94. Foam was sprayed on a sheet of release paper and cut into 6-inch X 2-inch X ½-inch (15.2-cm X 5.1-cm X 1.3-cm) pieces. The pieces were placed in a holder and exposed to flame for 1 minute. The flame is removed so that flame spread can be observed. The flame totally consumed the foam in 150 seconds.

One-part foams are not fire retardant. No fire rating under UL 94 can be assigned. Foams that have been engineered to seal conduits are often designed to be self-extinguishing under UL 94. These latter foams may carry an HBF Fire Retardant rating.

| Related Content: Understanding and Mitigating Manhole Explosions: An Interview with Stuart Hanebuth |

What is at Risk?

When water flows in a conduit through a failed seal, what is at risk? Is it more than just the cable (which is obviously expensive enough)? What else is downstream that can be damaged?

Analysis of the true cost of a cable and conduit installation should extend through the expected lifetime of the system itself, including estimated expenses for repair and replacement. The cost of premature cable failure, compromised electrical apparatus, damaged telecommunications equipment, ruined carpets and flooring, and even stained drywall due to failed duct seals should weigh heavily in this analysis. Consider, too, the potential cost of service outages. Is there any legal liability for any resulting damage?

The next step is to assess the source of the threat. If seals fail, will the potential damage be caused by worst-case rainfall, ocean surge, noxious gas buildup, animal infestation, etc. Can those threats be quantified? How much water head or gas pressure must be resisted for realistic integrity?

What is the Solution?

The solution is to analyze the risks and engineer the system. This includes specifying performance-based sealing materials. Don’t allow the entire system to be threatened by something many view as merely an inconsequential matter: sealing the conduit with a cheap and handy one-part canned foam.

| Related Content: Sealing Conduits for Resilient Electrical and Telecommunication Systems |

Ultimately, the solution is specification of alternate sealing products that meet performance parameters appropriate for the installation, such as two-part, closed-cell foams or mechanical seals. Sealants should be sourced from reputable manufacturers offering products developed, tested, and rated specifically for conduits.

After the 2011 tsunami disaster at the Fukushima nuclear plant in Japan, a worldwide reevaluation of flooding hazards and mitigation at all other nuclear sites soon followed. Suffice it to say that today very few of the critically important conduits at nuclear plants are sealed with one-part aerosol foam. Such seals are engineered for robust performance and long-term integrity. That attention to detail and quality could pay dividends at countless other cable installations worldwide.