Understanding How Conduit Sealants Perform in the Presence of Fire

Like most reputable building materials, sealants undergo testing prior to commercial availability. Their manufacturers work with third-party testing agencies to provide a rating or standards certification.

Safety regulations such as the NESC (National Electrical Safety Code) and NEC (National Electrical Code) typically require the sealing of conduits to protect critical systems and components from water, gases, and rodents. While there are various sealant options available to meet codes and requirements, a common type that is used are expanding urethane sealants. These types of seals are used in conduit systems that house electrical and communications networks within transportation hubs, office buildings, industrial plants, data centers, hospitals, and other critical infrastructure locations. Safety and reliability are crucial within these settings, and any opportunity to prevent disruption of electrical or communications operations is vital.

Fire is a risk that threatens any structure whether it comes from energized equipment within the building or from external means. Conduit networks and routes within buildings are a potential pathway for fire to spread if they are not properly sealed or if they are sealed with a material that does not have the proper fire performance rating. The use of building materials that limit the spread of smoke and flame and reduce the danger of fire is not only a best practice, but often code.

In this article, we examine how expanding foam sealants are assessed for fire performance based on industry standards and testing. The intent is to provide a better understanding of the differences between sealant materials based on their fire performance testing certification so that network owners, engineers, and installers can provide the right protection against fire.

What are the fire and smoke concerns?

At the basic level, it is important that the materials used in electrical equipment, components, and seals do not add fuel to a fire. Materials used in these applications should limit the spread of fire and even self-extinguish within a few minutes of flame exposure. When installed properly, expanding foam sealants and gap fillers can limit the air flow and the ability of oxygen to further fuel fire. In some cases, seals can act as a fire stop to keep fire from moving from space to space and are a form of passive fire protection.

How is fire performance tested?

Like most reputable building materials designed for the infrastructure construction and maintenance industries, sealants undergo testing prior to commercial availability. Their manufacturers work with third-party testing agencies to provide a rating or standards certification. Perhaps the most widely recognized third-party certification company that is used is Underwriters Laboratories, known more commonly as UL.

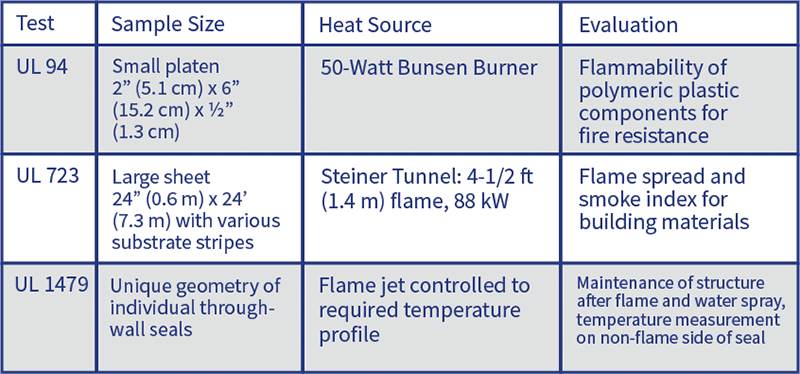

UL standards cover a wide range of products and systems, including building materials. UL has several test standards that measure fire performance. All the standards involve the application of flame followed by evaluation of the sample. Each standard reflects the varying performance requirements. In the following sections, we explore these test standards as they relate to expanding urethane sealants commonly used to block the passage of water and gases.

| Related Content: Is Meeting a Standard Enough?—An Examination of Duct Sealing Code Compliance. |

Testing Flammability of Materials

UL 94 – Tests for Flammability of Plastic Materials for Parts in Devices and Appliances, which is a straightforward test that measures a material’s ability to self-extinguish after application of a flame. In this test, a 2” x 6” x ½” (5.1 cm x 15.2 cm x 1.3 cm) block of expanding urethane sealant foam is exposed to a Bunsen burner flame for a duration of 1 minute. Following this exposure, the flame is removed and the subsequent burn time and burn distance are measured. To achieve the top rating, the sample should self-extinguish very quickly with no dripping or afterglow. Conformance to this standard allows the inclusion of the UL mark for component recognition. The intent of this standard is to identify system components which will not add to the fire in the event of exposure.

How is UL 94 used?

UL 94 has been used for many years as a basic standard to achieve UL recognition for sealant products. The recognition covers only the sealant, regardless of other materials used or the geometry of assembly. It is truly a test that looks at the sealants as components in a system that will not contribute to flame spread. In these cases, we might call the sealants fire resistant. The test is simple and straightforward, so recognition can be achieved at relatively low cost. Of great advantage is the ability to preview the test in virtually any laboratory, aiding in product development.

Testing Burning Characteristics of Materials

UL 723 – Test for Surface Burning Characteristics of Building Materials approaches the examination from a different angle. In this case, the expanding foam is seen as a building material, like drywall, caulks, adhesives, and wall coverings. The test itself is more rigorous than that of UL 94. Strips of urethane foam are applied to flameproof wallboard in 8-foot (2.4 m) lengths. These wallboards are loaded into a test specific apparatus to a length of 24 feet (7.3 m). Flame jets are applied to the sample’s leading edge for 10 minutes, and advancement of the flame along the urethane strips is measured as a function of the burn time. Simultaneous to this measurement, a sensor in the test chamber measures smoke generation. Results are reported as the distance that the sample strips burn along with a smoke generation number.

Rather than meeting a specific standard, these results may be compared with those of similar products. Flame spread and smoke generation are published under the UL symbol of classification. This standard is to measure the sealant’s susceptibility to fast fire exposure. Since the performance of the sealant is based on its ability to stop the passage of gases under ideal conditions, such a test can gauge how quickly this ability is degraded in the presence of fire, and to what degree the sealant will aid, or retard flame spread.

| Related Content: What You Need Know About Steiner Tunnel |

How is UL 723 used?

UL 723 (ASTM E84) is used to compare relative burning behavior of materials. Sealants listed under this category are often considered fire blocks because the materials themselves block the passage of oxygen or other gases that may fuel a fire. It is becoming a more popular standard for the classification of sealant products. It has the advantage of being the test of choice for a variety of construction and building products, making the standard potentially better known in the construction industry.

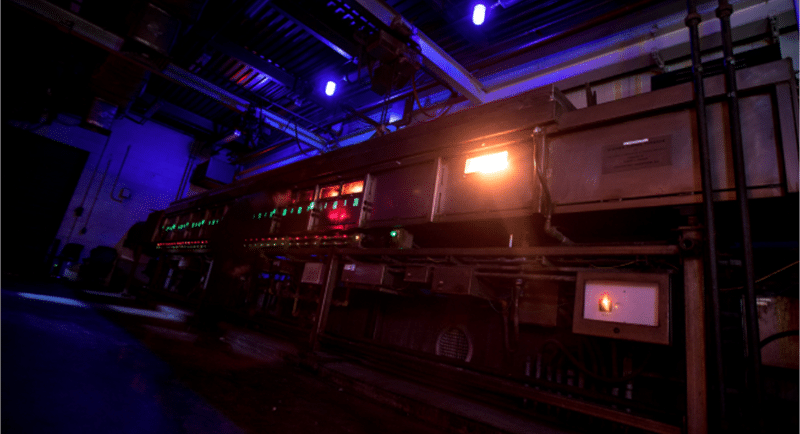

UL 723 (ASTM E84) uses a Steiner Tunnel Burn Chamber. This apparatus is used to regulate materials for interior building construction.

Fire Penetration Testing

UL 1479 – Fire Tests of Penetration Firestops is a much more challenging and involved listing. Here, samples of specific wall materials, conduits, and sealants are built to specific geometries. These wall samples are placed into the test chamber and exposed to a standard flame jet for intervals measured in hours. During this burning process, temperatures are measured on the non-flame side of the samples. At the end of the flame cycle, the sample is subjected to a forceful water spray. Results are reported based on burn time, temperature change on the non-flame side of the samples, and on the ability to stand up to the water spray. Results are published under the UL symbol of classification. Materials carrying this classification often list a high number of combinations of wall material, conduit, and geometry.

The UL 723 (ASTM E84) fire tunnel is large: 25 ft (7.6 m) long and 2 ft (0.6 m) wide with insulated firebrick walls.

Through-Wall Firestops are Very Specific

UL 1479 is very specific to through-wall firestops. Each iteration of wall material, conduit, and geometry with a specific sealant must be tested, involving a significant commitment of testing time and expense. Each of these combinations must be tested individually. The intent of this standard is to look at true protection. The testing evaluates the maintenance of structure after extended burning. Many sealants listed under UL 1479 have literally dozens of individual tests, addressing changing materials and geometry. In each case, the maintenance of the structure being tested is evaluated.

Through-wall firestops are only required in very specific fire code situations. Firestops often show inferior performance in controlling the passage of gases and water through the seal.

| Related Content: Why DIY Store Foams Fail to Seal Conduits |

Comparing the Types of Fire Testing

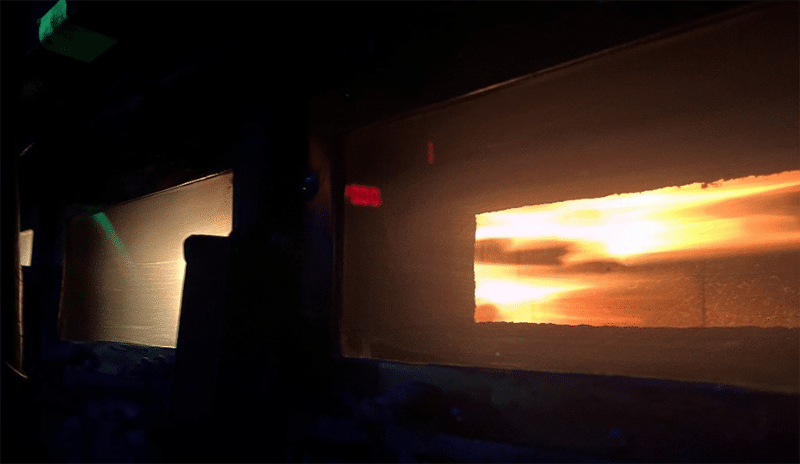

All the fire tests previously described use a high temperature flame. For instance, the UL 723 (ASTM E84) fire tunnel seen below, is equipped with a flame jet that puts out 5,000 btu per minute with a temperature of up to 1600°F (871°C) at the flame head. Showing good performance under any of these conditions is a positive attribute.

The UL 723 (ASTM E84) fire tunnel is equipped with a flame jet that puts out 5,000 btu per minute with a temperature of up to 1600°F (871°C) at the flame head.

Chart 1

Other Considerations Beyond Fire Performance

Having a more in-depth understanding of the differences between the various UL standards for fire performance testing allows network owners, engineers, and installers to make more informed decisions about selecting the right product to protect systems and critical assets from the effects of fire. The type of UL standard can help drive the choice of which expanding urethane sealant to apply based on the code requirements. While fire performance should be considered when choosing a sealant, it is just one factor that is part of the total decision matrix. Other factors to consider include the strength and versatility of the seal, and how well it seals out gas, water, and rodents.