Understanding and Mitigating Manhole Explosions: An Interview with Stuart Hanebuth

Stuart Hanebuth, noted expert on manhole events (smoke, fire, and explosions) and public safety, describes the challenges of recognizing and mitigating these dangerous events.

Serious manhole events, which can result in smoke, fire, and explosions, have been gaining more attention in recent years as the nation’s infrastructure ages. Potential consequences include fatalities, physical injuries, damage to property, and roadway accidents. A variety of causes can lead to these events, and utility engineers continually offer solutions with various degrees of success. In the interview below, Stuart Hanebuth, noted expert on manhole events and public safety, describes the challenges of mitigating these events.

Q. How often do manhole events occur annually?

A. We don’t know for sure how many underground structures there are in the U.S., but I estimate probably between one and two million. Based on what has been reported in the media and by utilities, I would estimate that nationwide there probably are between three and five thousand serious events per year that involve fires, explosions, or smoking manholes.

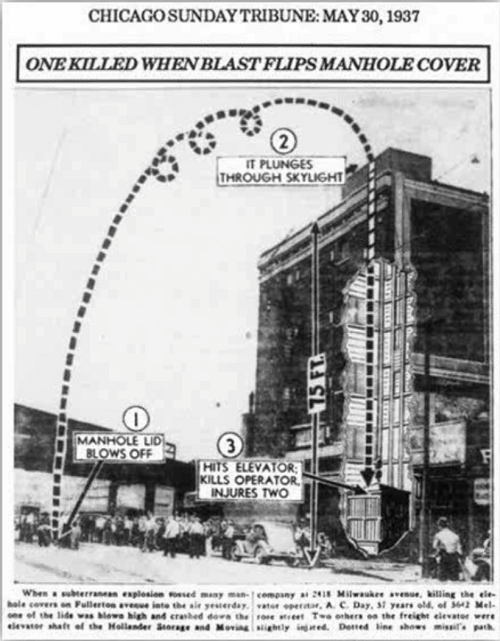

Q. Are manhole explosions a new phenomenon?

A. This newspaper clipping is from 1937. A manhole cover blew off and killed someone as it fell down an elevator shaft. It’s one of the earliest manhole events that we can find, evidence that these events have been around for a very long time.

Q. Could you please describe the main types of manhole events?

A. There are three broad categories of manhole events that are related to each other: smoking manholes, manhole fires, and manhole explosions. The most common type of event is a smoking manhole where a lot of smoke is coming out of an underground structure, but there is no fire or explosion visible at the surface.

By the way, when I say manhole, I mean any underground electrical structure with cables. It could be a vault, a service box, or any number of structures but it must be an underground structure. I use the term manhole for simplicity.

Q. What are the typical causes of manhole events and the concerns surrounding each?

A. All manhole events are sourced by two types of energy, combustion driven and electrically driven. Combustion-driven events are most often the result of anaerobic decomposition from the smoldering cable insulation. Electrically driven events result in a large arc with very high temperature. Each type requires a different prevention method.

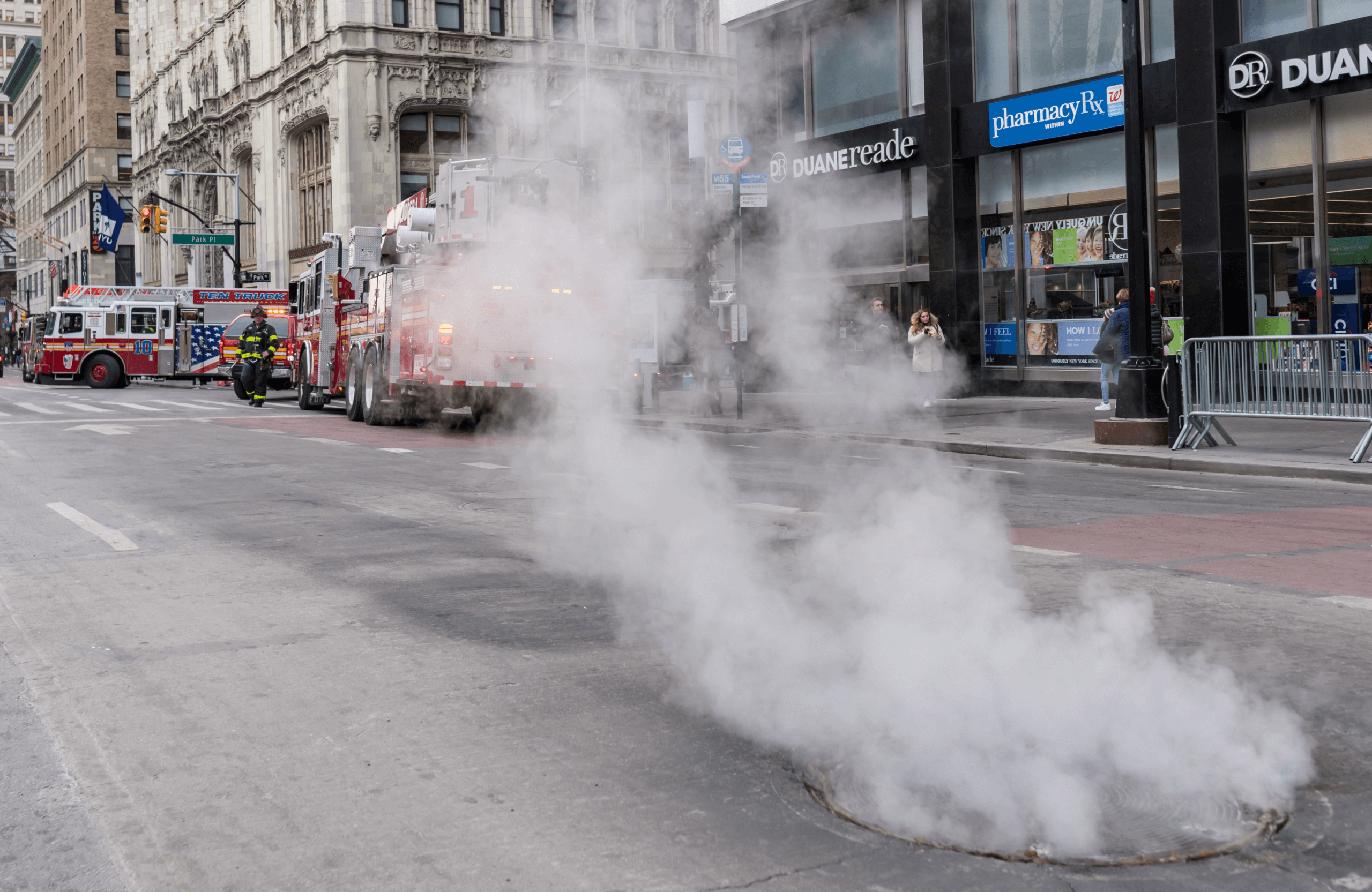

One example of an combustion-driven manhole event is pictured below. Firetrucks at the ready can be seen in the background, as the smoke and gases coming out of the structure may become a significant fire.

In electrically driven events, energy for the event comes from an electrical fault inside the structure, typically an underground cable. Most electrically driven events happen on transmission and medium-voltage cable.

A great example of an electrically driven event occurred in Buffalo, New York, several years ago and was caught on air during a news interview (video courtesy of WGRZ News). An underground cable fault resulted in an arc that superheated the air and blew the cover five stories off the ground.

These types of explosions are incredibly energetic events. It’s not uncommon to see covers blown many, many stories into the air. Incredibly, the cover did not hit anyone. But a 100-pound piece of metal flying into a person would result in a very serious accident. Besides physical injury and fatalities, these events can cause significant damage to property, roads, and other infrastructure. Finding effective ways to mitigate these types of events is very important.

| Related Content: Sealing Conduits for Resilient Electrical and Telecommunication Systems |

Q. Why are these visuals so dramatic?

A. Enormous amounts of energy can be released during a manhole event. Typically, when there is a manhole explosion, we are talking about somewhere between 6 and 40 megajoules of energy. It’s equivalent to between 3 and 20 sticks of dynamite.

Most of these events have a double peak, so there is an initial explosion and then a few hundred milliseconds later, there is another one. The first event is often an electrical arcing event that can vaporize all of the cable insulation. As the arc heats up, it forces all gases out of the structure, causing the lid to blow off. Once that arcing stops, the gases very quickly cool and cool air is sucked back into the structure. This brings the fuel-to-air ratio back into the right range, causing a second explosion.

Some manhole mitigation systems try to address this double peak by quickly preventing the second peak from happening. However, you need a very large opening to relieve this pressure. These are enormous pressures relative to the size of the cover. That cover must be moved out of the way very quickly, but the weight of the manhole cover works against any quick action, making these mitigation systems credible.

Q. What about combustion-driven events?

A. Most manhole events – 75% – are combustion-driven low-voltage events. The most common source of energy in these events is from the anaerobic decomposition of the cable insulation and, in many cases, the duct materials. The energy is coming from gases that are created by smoldering insulation. That burning material makes enormous amounts of carbon monoxide that is pushed down the duct.

We all know that carbon monoxide is toxic, but it is also incredibly flammable. Carbon monoxide has been forced into buildings or adjacent structures and has caused serious explosions. The gases are the more significant hazards.

Q. How are manhole events categorized by voltage class and energy type?

A. Annually, of all manhole events, 95% happen on low-voltage cables that are operating on less than 600 volts or so. Of these, 75% are combustion-driven events.

Low-voltage systems are designed to be fault-tolerant so they can sustain the slow arcing that goes on to burn the insulation for days, weeks, perhaps months. So that arcing and smoldering can be going on for a long time.

Transmission and medium-voltage events account for about 5% of all events. When they fault, they are cleared almost instantly, within a few cycles. In these events, arcing happens for 3 or 4 cycles, maybe longer if there’s a problem with the protection system, but they clear very quickly.

| Related Content: Duct Seals Prevent Ruinous Water Damage |

Q. Could you please elaborate on how decomposition of cable insulation and duct materials contribute to manhole events.

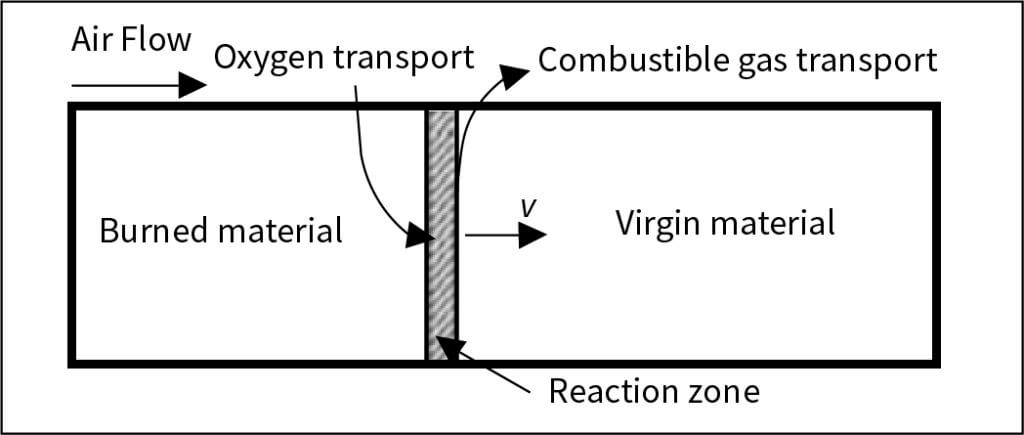

A. Figure 1 illustrates what happens. If you run a duct with a low-voltage cable in it and there is a small crack in the insulation, you will get tracking and arcing across that crack. The arc probably draws less than an amp in most cases, so it does not look like an electrical fault to the distribution system. The energy keeps flowing out to this fault. That small arc is heating the cable and insulation, which starts to smolder. The smoke contains several gases, including carbon monoxide, hydrogen, methane, and other gases.

FIGURE 1

Most of what is burning and causing fires and explosions is carbon monoxide. The hydrogen escapes through the cracks and pores in the ducts so it’s pretty inconsequential. The duct decomposition process also leaves behind almost pure carbon dust. So, there is carbon dust, carbon monoxide gas, some hydrogen, and other things coming out right at the flame front, the reaction zone. Those gases must go someplace so they are flowing to the low-pressure end of the system, in other words, the manhole cover. You need airflow on the order of about 0.2 meters per second to support this process. At that rate, the airflow will force the flame front along the cable and duct material where it will continue to create large amounts of gas.

It is important to note that you must have the airflow. Without it, the reaction zone or the flame front cannot be moved down the cable. The gas has no place to go, and the fire essentially self-extinguishes. There will be arcing, and it may progress into an electrically driven event, but an electrically driven event inside of a duct is much less severe than a combustion-driven event occurring in a manhole.

Q. Could you please elaborate on electrically driven events?

A. Electrically driven events comprise about 30% of all manhole events where 5% are medium voltage events and 25% are low voltage events. Typically, there is a large arc, an electrical short, and a very high temperature. The arc melts and vaporizes the insulation and conductors. That arc can ignite combustible gases as well, which may cause a secondary explosion. These events are a little more difficult to interrupt because they rely on very sensitive fault protection systems.

In many of the serious electrically driven events, there is a major problem with the electrical protection equipment. The relay settings are incorrect, or the system allows the fault to persist longer than it should. The longer that fault persists and the more heating, burning, and consumption of insulation and conductors go on, the more fuel is created for the fire. Most electrically driven events that start fires or cause covers to blow off occur in the structure. They generally do not occur in the duct.

Q. Would a poor or faulty splice during installation of a cable lead to an event?

A. It would, but most of the time, it would not cause the cover to dislodge or blow off. Most electrical faults are cleared quickly by protection systems and do not appear on the surface.

Q. What is the IEEE Working Group P2417 doing to develop a guide that addresses serious manhole events?

A. The Working Group P2417 has developed a guide for smoke, fire, and explosions in underground electrical structures. The working group includes about 50 utility engineers that meet twice a year during the IEEE Insulated Conductors Committee Meetings. Our goal is to capture all relevant information regarding manhole events and make it easily accessible so that manhole events are mitigated. This is a guide, not a standard, so there are no mandatory requirements in this document. It mainly describes best practices, but no recommendations are made. The guide is available for purchase from the IEEE.

The guide includes a chart that focuses on the combustion zone and possible methods for stopping manhole events. The chart illustrates the role of airflow in combustion-driven events. Our premise is that if airflow is restricted to less than 0.2 meters per second, the fuel in the combustion zone will be subsumed and gas generation will end.

Q. What mitigation measures are being tried currently and what are the benefits and drawbacks to each?

A. A few years ago, a Canadian utilities company had a large number of secondary cable failures. They inspected the cables and found that about 5% of them were damaged during installation. Cables were being dragged across joints in the ducts, or other duct obstructions, and the resulting damage allowed debris to get into the ducts. This damaged the insulation and caused the latent faults. A system was developed where the ends of the cable were capped, followed by a pressure test to see if the jacket could hold the air pressure. The system worked but it was too complex for the field.

| Related Content: Polywater® FST™ Sealant Solution Video |

Some utilities fill manholes with inert materials such as sand. This stops the airflow through the duct and prevents the accumulation of gases in the structure. It is fairly effective but when you need to access the structure for repairs or other work, a vacuum truck must be brought in to remove the sand before the crew can get in.

Many utilities quickly inspect all of their structures after an event. About 10 years ago, a major utility in the U.S. conducted a study on visual manhole inspections and determined that there were no reductions in manhole fires or explosions after they inspected their entire system.

There are benefits to systematically ensuring that the portion of cables that are visible is in good condition. But more than 95% of the cable is hidden up the duct, so visual inspection of the 5% of cables that can be seen is not really effective in preventing fires or explosions.

Q. What about early detection of precursors for manhole events?

A. Contact voltage detection is one method where a crew drives around and looks for latent faults that are forming a conductive pathway to the surface and appear as energized roadways or sidewalks. Some studies have shown this method can reduce events by 20% if the monitoring is done frequently and consistently, which is not always possible.

Arc fault detection is probably the most promising idea in the early detection. There is a specific electrical signature that is associated with an arc fault but separating it from the baseline noise on the system is very difficult. The arcing fault looks a lot like an arc welder or a motor start-up, so it is difficult to separate an arcing event from a normally operating piece of equipment.

Q. Could you describe volt or manhole monitoring systems?

A. We’re seeing a lot of interest in volt monitoring systems. These systems can measure a variety of parameters, including the presence of smoke. If the system detects smoke in a manhole, it sends an alarm back to a control center that will dispatch a crew to respond. The goal is to get there before enough combustible gases are generated to cause a fire or explosion.

The challenge with this method is that alarm responses in the maintenance system can be overwhelming when there is increased demand for other services. There may be customer calls for power outages, trouble with residential service, or other issues at the same time as a manhole event, creating a significant challenge in timely response for the maintenance crew.

Q. Are there any other mitigation tools that you’d like to discuss?

A. Some utilities have installed vented manhole covers. The theory is that if you cut some slots in the cover, that will allow the release of gases and avoid an explosion. But when there is an explosion with enormous pressures and speeds, the vented cover performs much the same way as a solid cover does. In fact, vented covers may be enhancing airflow through the duct and increasing flame propagation.

Another mitigation method is to hold the cover down. The photo below shows the results of a test involving a self-restraining cover with a latch so when there is an event, the cover lifts up, and the latch holds it to the metal ring where the cover is mounted. In many cases, self-restrained covers can help to mitigate the effects of an explosion.

Q. There is some disagreement about sealing conduits as a solution to manhole events. Why do some utilities not want to seal conduits as a preventative measure?

A. Utilities think they will not be able to maintain the seals. But we are not really talking about seals. When they are preventing manhole events, they act as airflow restrictions so that air is not moving through the duct. Granted, it can be overwhelming to think about sealing millions of duct ends throughout the country. But really, I don’t think utilities have a good reason to not seal ducts. We probably need to do a better job of educating utility engineers and public safety officials about the benefits of airflow restrictions and how they can provide a solution to serious manhole events.

Have any questions?