The Science of Cable Lubrication: Film Thickness and Quantity Recommendations

How much cable pulling lubricant is needed to safely install cable? The answer is simple: enough to coat the space between the two surfaces that rub together — the cable jacket and the conduit inner wall. This easy answer belies the deceptively difficult practice of adequate lubrication because most of the cable is hidden from view inside the duct. Installers recognize the need to lubricate cables as they are pulled into duct. They’re often less confident, however, about how much lubricant to use, because it is “invisible” until the cable exits the duct.

How Much Lubricant Should Be Used? (Using film thickness to determine lubricant quantity.)

Lubricant works best when it fully coats the two surfaces that rub together. The theoretical answer to the quantity question is based on film thickness. To calculate an estimated quantity, we started with a typical lubricant coating thickness of 10 mil (0.01 inch) or about 25 mg per cm2. Using the surface area of the duct, it is possible to calculate volume requirements. This is published as a quantity recommendation formula:

Q = K x L x D

Where:

Q = quantity in gallons (liters)

K = conversion factor, 0.0015 (0.0008 metric)

L = length of duct run in feet (meters)

D = ID (Inner Diameter) of the duct in inches (mm)

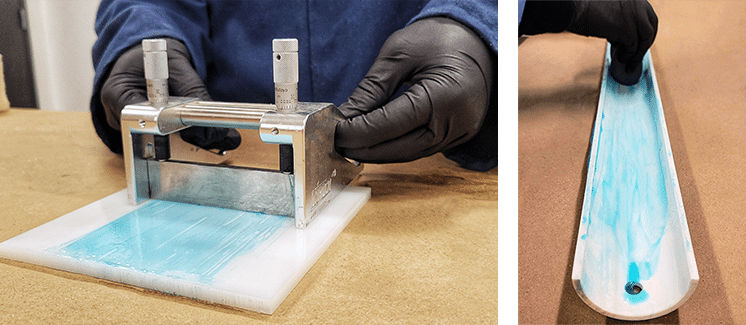

The quantity formula is based on a theory of film thickness. This produces a generous layer of lubricant, like a thick coat of paint. To better visualize this coating, a gel lubricant has been dyed blue and spread onto a white duct, and is shown in Photos 1 and 2.

Photo 1: Here lubricant is coated to a controlled thickness of 0.01 inch (.25 mm). This makes a thin, continuous coating of lubricant.

Photo 2: the same coating of lubricant is applied as a weight per area. Note that the coating is not as perfectly uniform. It does coat the entire surface .

Experience shows that theory matches practice nicely. When the formula was first developed, quantity recommendations aligned with typical field practice. For a 1,000-foot (300 meter) pull in a 4-inch (1,000 mm) duct, typical lubricant usage is 4 to 10 gallons (16 to 40 liters). Ongoing experience continues to support these quantity recommendations. These guidelines have served end users well for decades. Whether estimating how much lubricant to use for a routine pull or how much to purchase for a large job with many pulls, the lubricant quantity formula is an excellent starting point.

| Polywater’s Lubricant Quantity Calculator |

Does More Lubricant Lower COF?

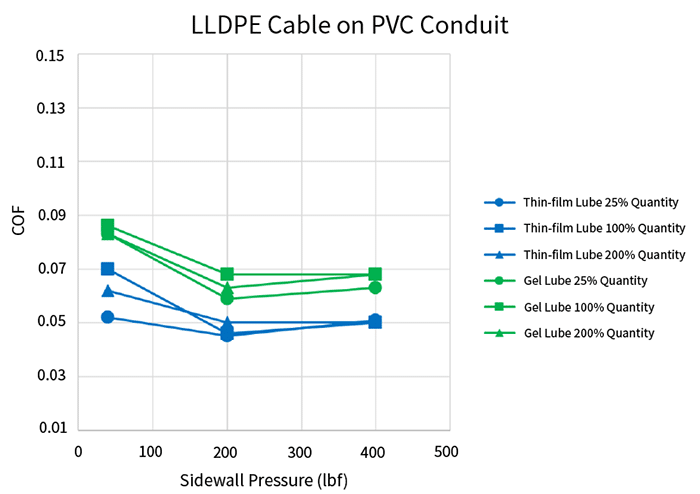

How does the coefficient of friction vary with lubricant film thickness? Is it possible to “starve” the cable so that there is not enough lubricant to be effective? If excess lubricant is used, does the cable have to “plow” through the lubricant, effectively increasing COF? To answer these questions, coefficient of friction was measured under varying conditions:

-

- Lubricant Type – Both Gel and Thin-Film lubricants were tested.

- Lubricant Quantity – 25%, 100%, and 200% of the recommended quantity.

- Sidewall Force was also varied.

Using a Friction Table test, sidewall force can be varied to simulate the behavior of a lightweight cable as well as a heavy cable that may be pulling against the conduit wall with high force. Lubricants were coated at the quantity recommendation (100%), as well as twice that (200%), and one-fourth the recommendation (25%).

Results are shown in Graph 1 below. Lubricant use reduces the coefficient of friction. This effect is independent of lubricant quantity used.

GRAPH 1

Friction reduction is mostly independent of lubricant quantity. Less lubricant will result in similar friction reduction. This is because the lubricant was carefully and evenly applied to the test cable. An effective quantity of lubricant is governed by what is needed to get lubricant to all points of the cable rub.

| Related Content: Measuring Friction on Polywater’s Friction Table |

Note: Specialty thin-film or blowing lubricants are concentrated and reduce friction even at extremely low film thickness. Use recommendations for such thin-film lubricants are much lower than the standard recommendation and were followed in this testing.

Is It Possible to Use Too Much Lubricant?

At 200% of the recommended quantity, the lubricant continued to perform as anticipated. Excess lubricant will flow to the sides and in front of the leading edge of the cable. No negative effects were found.

On the Left, 200% Gel Lubricant, “plowing” is visible, but does not increase friction.

On the right, 200% thin-film lubricant excess will pool in the duct.

Research typically shows that the friction factor decreases under high sidewall pressure.1 Some sources speculate that this is caused by the forces needed to overcome the shear force of the lubricant.2 This effect is minimal, and friction reduction is independent of lubricant viscosity. The chemistry of the lubricating agents, the cable sheath and duct material play a larger role in COF determination.

How Low Can You Go?

What happens with thinner and thinner coats of lubricant? Of course, there is a physical limitation to how thin the lubricant can be spread. Specially formulated thin-film lubricants are concentrated and can be coated to a thin film as their name implies. If lubricant is present between the two moving surfaces, it is working.

The more important consideration is how well the lubricant will “carry” and spread through the entire length of the pull. Long pull lengths, multiple bends, dirty or water-filled conduits, high cable fill, etc. are factors that require increased lubricant quantity.3 While there are few if any cases of too much lubricant, there are cases where not enough lubricant was used. This can cause high pulling tension and result in problems such as overworked equipment and damage to the cable systems. Laboratory data shows that very little lubricant may be required to reduce friction. Field experiences show that using a generous amount of cable lubricant is worth the time and effort.

| Related Content: FAQ – Cable Pulling, Lubrication, and Tension |

Lubricant Wetting, Coating and Spreading

One characteristic of a good cable lubricant is its ability to self-spread and coat surfaces throughout the pull. An important property of a performance cable lubricant is called surface wetting. To understand wetting, consider what happens when you put water on a newly waxed car. It beads and forms droplets. In the same way, water can bead on the slick surface of a polyethylene cable jacket. It can also be pressed out from the cable surface as it is forced against the conduit wall, especially around bends. For example, a poor “lubricant” can be squeezed out from between cable and conduit. This lack of wetting and persistence is easily identified with friction testing. This type of “lubricant” does not lower the COF.

A good cable (performance) lubricant will flow and spread throughout the cable and conduit surfaces. It will cling and stay coated on the cable as it moves through multiple bends. To test this, a cable was pushed through a conduit with 420 degrees of bend. After it was pulled through, the lubricant coverage was observed. This was repeated for three trials. In each test, the lubricant was coated using different techniques.

-

- A bead line of lubricant was applied to the top portion of the cable as it entered the conduit.

- Cable lubricant was spread all the way around the cable by hand.

- The conduit was prelubricated with lubricant, and the unlubricated cable was pulled through the conduit.

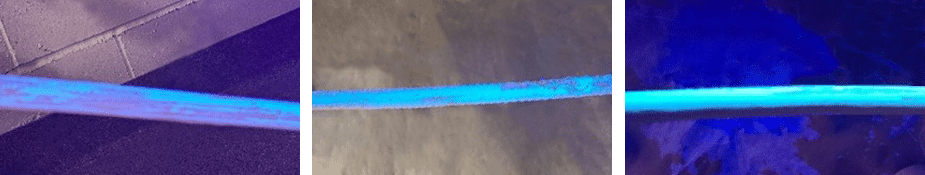

The percentage of lubricant coverage was visually estimated. Fluorescing dye was added to the lubricant, and cable jacket was observed using a black light. Lubricant coverage was estimated as shown in the photos below.

Image 1 shows ~40% coverage, Image 2 shows ~75% coverage, Image 3 shows ~90% coverage.

This test shows that performance cable lubricants continue to spread and coat the surfaces as the cable moves through the duct.

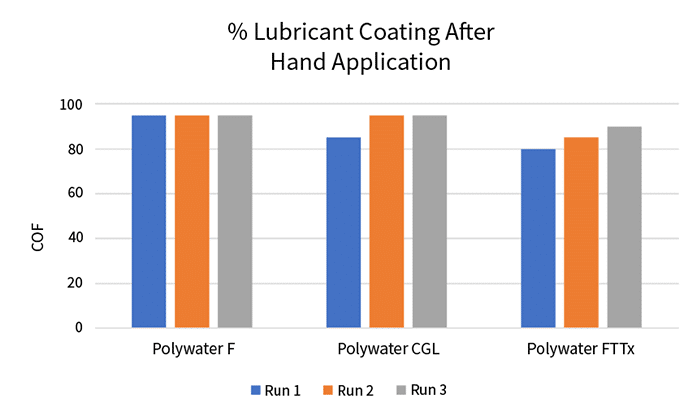

The first test is a controlled, hand application. Lubricant is smoothed over the entire surface of the cable, and the cable is pulled through 15 ft (4.6 m) of unlubricated reeled conduit. As the cable moves through the system three times, the lubricant coverage on the cable is observed.

GRAPH 2

| Related Content: A “Pour” Explanation |

This test shows that performance lubricants stay coated on the cable jacket even as the cable moves across the unlubricated conduit surface. Some lubricant has transferred to the conduit surface and continues to spread. It will recoat the cable as the cable passes through it. This action increases the coverage area as the cable moves through the duct.

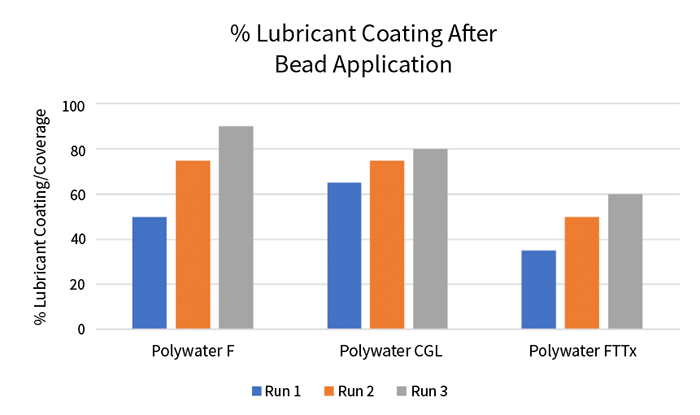

In the second test, lubricant is applied in a narrow bead across the top of the cable. The cable is then run through the unlubricated duct reel and coverage is observed. The cable is pushed through the reel another two passes.

GRAPH 3

This test shows the lubricants self-spread and coat the surface of the cable as the cable moves through the conduit. The percentage of coverage increases after each pass for all three types.

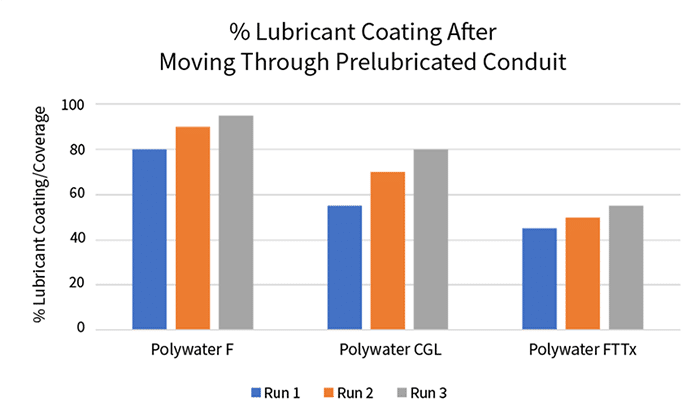

In the third test, the cable is not coated at all. It is pulled through the lubricated conduit reel. As the cable moves through the duct, the lubricant transfers to the cable surface.

GRAPH 4

In this scenario, the performance lubricant continues to spread and coat the full surface of the cable. After three passes, all lubricants tested have coated more than half the cable surface. Prelubrication of the conduit is an excellent way to ensure good lubricant coverage.

Polywater FTTx (thin-film lubricant) is used at a much lower quantity. It is more persistent on the coated surface and does not transfer as well as traditional lubricants. Thin-film lubricants like Polywater FTTx stay coated on the surface to which they are applied so that there is a complete lubricating layer between the cable and duct.

| Explore Polywater Lubricants |

Conclusion

A performance pulling lubricant is paramount to safe cable installation. Yet lubricant is only functional if it gets to where the rub is. Good prelubrication and coating techniques help reduce the COF and result in lower, more predictable pulling tensions. Using generous quantities of lubricant increases the odds of thorough coverage. A high-performance lubricant that self-spreads and stays coated further enhances the application process.

Research proves that thorough application of minimal quantities of a premium lubricant can yield surprisingly low COFs. This offers potential cost savings by reducing the quantity of lubricant required. However, perfect application in a laboratory setting and real-world application in the field are often two different things.

Excess lubricant doesn’t appreciably increase COF, but it does help coat the cable and conduit. This ensures lubricant reaches the friction points. Lubricant is also inexpensive, certainly cheaper than damaged or stuck cable. The risk of delayed installation, increased labor costs, equipment failure, and/or cable damage is higher with inadequate lubrication. Thus, when calculating lubricant quantities, best practices dictate that it is better to err on the side of too much lubricant rather than too little.