The Role of Specialty Cleaners in PPE Safety: Q&A with Randy Barnett, NFPA Certified Electrical Safety Professional (CESCP)

Randy Barnett, an NFPA certified electrical safety compliance professional with 35 years of maintenance and training experience, gives insight on specialty cleaner's role with PPE and electrical safety.

Dirty rubber goods such as gloves, jumpers, blankets, and sleeves are contaminated with a host of grimes that over time can lead to electrical tracking and unsafe conditions. The contaminants can also mask physical damage such as nicks, cuts, and cracks that are equally dangerous for workers. These contaminants include tree sap, pesticides, bug sprays, sunscreens, dirt, dust, road salt, bird droppings, body oils, creosote, fertilizer, hydrocarbon grease, etc. IEEE Standard 978 recommends daily inspection of live-line equipment to mitigate the risks.

In this Q&A, Polywater sits down with Randy Barnett, an NFPA Certified Electrical Safety Professional (CESCP) and author of numerous topical articles and books, to explore his viewpoint on how specialty cleaners improve the safety of PPE and aid compliance with regulations.

Q. Welcome, Randy. Can you provide a bit of background on your experience and expertise?

A. Yes, thank you. I have been involved in the electrical industry for well over forty years. I learned the electrical trade in the US Navy nuclear submarine service as an electrician. From there I went to work in power plants, railroad locomotives, manufacturing plants and working heavy industrial electrical construction. I became involved in training electrical workers over twenty years ago. I am a Certified Electrical Safety Compliance Professional through the NFPA and certified as an electrical inspector through the National Construction Code Council. I am the author of the textbook “Commercial and Industrial Wiring” and numerous electrical articles.

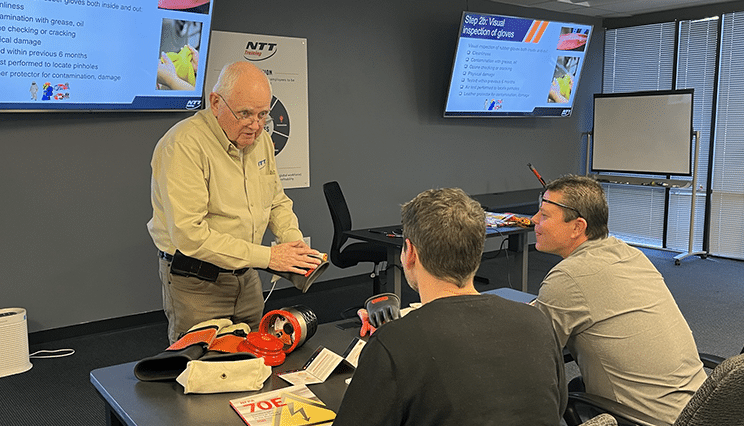

Q. You are truly a fount of knowledge on a broad spectrum of electrical safety matters, but we want to focus on the specific topic of cleaning PPE. Last May you published an article in EC&M entitled, “Five Steps for Creating an Electrically Safe Work Condition.” Generally speaking, do specialty rubber goods cleaners play a role in your “Step 2: Select and Inspect PPE”?

Q. You are truly a fount of knowledge on a broad spectrum of electrical safety matters, but we want to focus on the specific topic of cleaning PPE. Last May you published an article in EC&M entitled, “Five Steps for Creating an Electrically Safe Work Condition.” Generally speaking, do specialty rubber goods cleaners play a role in your “Step 2: Select and Inspect PPE”?

A. Yes, absolutely. Insulated rubber goods are the last line of defense against shock injury. We don’t wear insulated voltage rated gloves or sleeves to intentionally make contact with live terminals. The gloves are “just in case” you do; you will be protected. So, rubber goods are truly that last line of defense. If any rubber insulated good leaks air, it would leak electricity. So, proper inspection for discrepancy items, such as pinhole-sized openings in the rubber, prior to use is not only required, but also critical. And how do you inspect something you can’t see? You don’t! Cleaning is first needed.

Unfortunately, there are a lot of different contaminants out there in the workplace. Chemicals, hydraulic oils, solvents, even certain hand lotions can contaminate our gloves. These contaminants may not even be visible on the rubber but can hide defects like small openings and discoloration. Our insulated rubber products, since they are made of rubber, are subject to deterioration from petroleum-based products like the types I just mentioned. So, in addition to being concerned about inspecting for rubber goods defects, we must be concerned about removing any contamination that can deteriorate the quality of the rubber.

The question becomes, “What products should I use to clean my rubber goods?” Manufacturers’ recommendations can be anything from “Use mild soap and water,” to “Use a bleach-free mild detergent,” or to a specific brand-name product. I don’t know which brand of ‘mild soap’ is best, if any. Bottom line, we need to look for a product that does an excellent job of cleaning the rubber material, does not leave a residue and does not cause damage to the rubber. These basic requirements are specified in the ASTM F496, “Standard Specification for In-Service Care of Insulating Gloves and Sleeves.” So, we need a good quality rubber goods cleaner not just for compliance, but to ensure that the last line of defense functions at its best.

Q. So, it’s safe to say that clean PPE helps reduce the risk of injury and death from arc flash or shock?

A. Yes, definitely. Tracking across rubber goods has always been a concern. Inadequate inspection of rubber goods is just asking for trouble. Keeping it clean is one big step in our electrical safe work practices.

Q. To what extent are the arc flash, and the shock boundaries of limited and restricted approach distances affected by clean and functioning PPE?

A. Well, the boundary numbers themselves are not affected by what you wear or what condition it is in. Our job is to understand and respect those boundary numbers and ensure all of our PPE meets the requirements to enter those boundaries. Let me explain each boundary.

The “Arc Flash Boundary” is the distance from live parts where we begin to suffer second degree burns should an arc flash occur. We wear arc-rated clothing at or above the incident energy levels expected to protect our bodies from these burn injuries. The hands are also required to be protected. Voltage-rated rubber gloves with leather protectors are considered adequate protection against burn injuries from the arc flash. Obviously, none of this PPE, including the rubber can have any flammable contaminants such as oil or grease on them. Otherwise, there is good chance the worker will end up with burn injuries.

| Related Content: Cleaning Rubber Goods for Safety |

The voltage-rated rubber goods provide shock protection. The “Limited Approach Boundary” is the distance from a live part where a shock hazard is considered to exist. For example, the Limited Approach Boundary for a 480-volt system is 42 inches. The “Restricted Approach Boundary” is twelve inches at 480 volts. Any item taken within that twelve-inch boundary must be insulated. This includes not only tools and test leads, but our hands, as well. So, if we are going to do something fairly simple, like take a voltage reading, we must wear voltage-rated rubber gloves. If our arms will enter the Restricted Approach Boundary, as is common at higher voltages since the boundary extends out further with increased voltage levels, then we may need voltage-rated rubber sleeves in addition to the gloves.

Q. So, you define making contact as not just touching energized parts with gloved hands but including live terminals with test leads or insulated tools. These actions are only safe with clean and undamaged PPE?

A. Certainly. The discussion part of making contact includes items such as test leads being placed on live terminals is a statement right out of the NFPA 70E Standard for Electrical Safety in the Workplace. Personnel protection involves more than just one safe act or piece of PPE. It must all work together as one chain. If any link fails, trouble can result. Of course, workers are trained to recognize energized from deenergized parts and the performance of safe work practices. When using test leads the fingertips are very, very close to live energized parts. Inadvertent movement can result in accidental contact with that live terminal or part. The insulated rubber glove is what then prevents electric shock.

Q. How frequent are injuries due to improper PPE maintenance? Is there data or resources available on the topic?

A. Unfortunately, I don’t know of any place where such statistics are kept. The Bureau of Labor Statistics are the ones who keep track of electrical injury data. We do know, however, that in 2020 there were 126 electrical fatalities on the job and about 2,000 electrical injuries. While the BLS analyzes these by industry and worker classification, I have not seen anything specifically on faulty PPE. However, we know that if appropriately rated rubber goods, properly cleaned, inspected, and are correctly used, most all the electrical fatalities can be avoided.

| Related Content: Video: Live-Line Equipment & PPE Cleaning Solutions |

Q. Do you have a story or anecdote about unsafe rubber goods that you can share?

A. Oh yes! And of course, it’s always embarrassing to look back. As I mentioned, I began my career in the naval submarine service, and that was in the 1970s. OSHA had just come into existence and what little electrical safety rules we had back then were inadequate. For example, for our thirteen electricians we had one set of voltage-rated rubber gloves. To make the gloves comfortable to wear we used baby powder on the inside. It was years later we found out the particular baby powder we used contained petroleum-based products that deteriorates rubber. We did have one very serious shock incident when a person I was working with made contact with his hand on a live 480-volt busbar in the back of a switchgear. Obviously, inadequately maintained, and improper use of the gloves did not offer protection.

Much more recently I was performing a field work audit required by the NFPA 70E standard. I was watching a young lineman inspect his PPE before climbing a pole to work on an energized 480-volt feeder. He was very knowledgeable and passionate about his work. When he pulled out his voltage-rated rubber gloves to inspect them, I noticed the glove color was yellow, which was fine, but they were very, very dirty. When he performed his air test on the gloves I was not satisfied with the procedure he used to check for leaks. I asked him for the gloves so I could demonstrate proper inspection techniques. I pointed out how the soiled areas were preventing proper visual inspection; but I found nothing wrong with them from what I could see. When I did the air test, I easily found a small slit in the working area of the glove. That was a terrible accident waiting to happen. We called in and had the supervisor bring him a new pair.

Q. A quality rubber goods cleaner eliminates the potential for tracking but can also reveal hidden damage on a tool that should be removed from service for refurbishment or replacement. Which of these PPE risks is more prevalent and important, or does it matter in your opinion?

A. Good question. When it comes to tools it is the same as the rubber goods we just discussed. Contamination both allows tracking and covers up damage. The primary purpose of insulated hand tools is to prevent an arc flash in the event you were to drop the tool or somehow get it across two live terminals at the same time. Damaged insulated hand tools are typically required to be destroyed and not allowed to be repaired or refurbished. Tracking across a hand tool can cause an arc flash. Dirty insulated tools are not an option for electrical work.

| Related Product: Polywater Type RBG Rubber Goods Cleaner |

Q. Do safety training programs adequately cover the proper cleaning and inspection of rubber goods?

A. I think most training programs do a pretty good job. Obviously, some are better than others. I find instructors are knowledgeable and experienced on the topic. I always like to point workers towards the inspection procedures in the ASTM standards. I find reviewing the requirements for cleaning, inspection and maintenance are always good topics for tailgate safety meetings. Of course, we can always learn more, and good instructors strive to do that.

Q. Some may interpret safety regulations to require only routine inspection of PPE, with cleaning deemed necessary only as a result of inspection. But to discover hidden damage such as nicks and cuts, shouldn’t the cleaning occur before inspection?

A. That’s just what the standards say: “Inspect daily.” We already have enough to worry about on the job. Whether or not our PPE is adequate is not something we should have to think about when doing electrical work. Inspecting daily before use only makes sense. Too many things can happen to damage PPE in between uses. Yes, inspect it daily.

Q. Do you think awareness of the existence of specialty cleaners is high enough? Are these safety products and procedures used routinely, or is more training needed?

A. Definitely not enough awareness. The standard in the classroom and safety meetings is “Use mild soap and water.” I think that has been the mantra for many, many years. After all, it is what the manufacturers told us to use. I would like to see more manufactures recommend products that meet certain ASTM standards, like the ASTM F496. We already use specialty cleaners for live line tools such as hot sticks. It needs to be the same for voltage-rated rubber goods including gloves, sleeves, blankets, line hoses and the insulation on temporary protective grounds, as well.

Q. With regard to cleaning and inspecting PPE, do you refer to safety regulation compliance in your training programs? If so, is the focus on IEEE, OSHA, NEC, or NESC? Which specific codes do you highlight?

A. Yes, we always review the compliance requirements. The NFPA 70E Standard for Electrical Safety in the Workplace is the most often used for training as it is the most thorough. It is the “how-to” for complying with OSHA electrical requirements for general industry. 70E requires PPE to be maintained in a safe, clean, and reliable condition. The standard also requires inspection daily before use.

Q. A variety of common solvents will clean PPE, but many are incompatible with rubber goods and can cause serious and potentially dangerous damage. Only cleaners specially formulated for rubber goods should ever be used. Is there enough industry awareness of this issue? Do safety training programs address the matter?

A. No. My perspective is most, if not all training programs I have been involved with, lack adequate information on the importance of and methods of cleaning voltage-rated rubber goods. I read a good deal on electrical safety, visit trade shows and watch the videocasts. The information is just not readily available. We need to do a better job of broadcasting cleaning and inspection procedures and methods. Trainers want the latest technical content and want to teach the best industry practices. We must always strive to do the best possible when it comes to protecting workers.

Have any questions?

Related Resources:

Barnett R. 2022. Five Steps for Creating an Electrically Safe Work Condition

Dahlke S. & Fredericks T. 2006. Cleaning Rubber Goods for Safety: https://www.utilityproducts.com/safety/article/16003887/cleaning-rubber-goods-for-safety