The Polywater® Friction Table: Personal Perspectives

Polywater® invented a measurement device that we call the “Friction Table” to test lubricant effectiveness and help customers optimize cable pulls. Sheri Dahlke, technical director, and Ron Raedeke, application engineer, have extensive experience in the table’s operation. In the following interview, they share insights on how it has helped customers achieve their project goals.

“We have a large body of data containing thousands of friction measurements, which has made it possible to reliably predict lubricant performance in the field.” -Sheri Dahlke, Polywater, technical director

Why was the friction table developed?

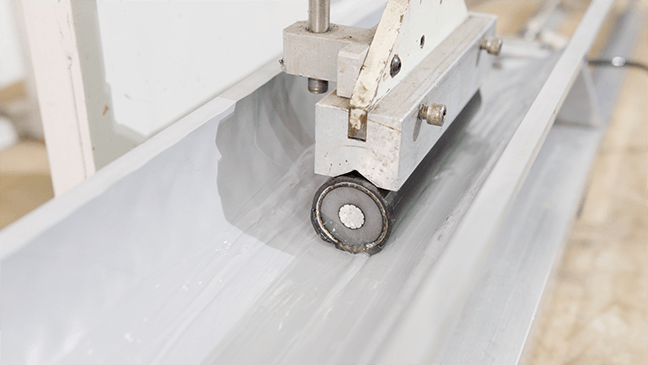

Sheri: The table was born of the need to simulate cable pulls in the lab where various factors affecting friction can be adjusted and the results measured. It was developed as an accurate and efficient way to measure friction coefficients on lubricated cables and conduits during pulls. Lower friction is essential for successful pulls without cable or conduit damage. The table allows us to apply the scientific method to lubricant testing and development.

The friction table was created concurrently with our lubricants, and today is instrumental in testing Polywater lubes on new and evolving cable jackets and conduits—sometimes resulting in new, specialized products. It provides a reliable way to predict lubricant performance in the field.

Ron: This testing ability allows a good comparison of different lubricants on various combinations of cable and conduit materials. A high friction coefficient puts more strain on cables and increases sidewall pressure, potentially leading to expensive damage. The right combination of lubricant and cable/conduit materials decreases tension, thus reducing damage and increasing cable life expectancy.

| Related Content: Measuring Friction on Polywater’s Friction Table |

What were some of the issues when developing the friction table?

Sheri: Going back to physics class, friction is measured on an inclined plane. When an object starts to slide down the plane, the friction coefficient is determined. This type of friction measurement does not reflect actual field conditions. To reflect the real world, we measure kinetic friction as the cable moves. Additionally, polymeric cable jacket materials have softness and give to them, and act differently under sidewall pressure. The friction table provides more realistic modeling of how friction actually works in pulling environments.

Ron: Over time, we used other friction measuring devices and compared these numbers to those from our friction table. We found the measurements to be very similar among the devices though they required more cable and conduit, and more setup time. We also found that it was difficult to change from one lubricant to another on these devices. Our friction table minimizes testing time, which allows more sampling and accumulated data to help refine results.

Sheri: We like that our friction table is fast. It provides a lot of flexibility, especially for rigid materials like metal conduits. We run friction testing with many different types of cables, conduits, and lubricants. We also have other equipment to test and measure issues such as cable jamming and water-filled conduits.

Our friction table has improved over time. There was little automation in the first version. For example, we used a rubber mallet to initiate static friction. We didn’t measure the downward force load. Later, we started measuring friction with pneumatic pressure and found that the load cell was more accurate. Today, we can measure the load every tenth of a second through an entire run. We’ve really perfected our measuring techniques.

What are the key steps for conducting a successful friction table test?

Ron: We use real cables, conduits, and lubricants, and always start with clean materials to ensure consistent results. We clean cable and conduit samples with a two-step process: first a hydrocarbon cleaner, followed by alcohol. This helps minimize contaminants. Occasionally, we can’t clean the samples adequately, but we always report any adverse conditions encountered.

Sheri: We have a large body of data containing thousands of friction measurements. Each test is the product of four or five runs with twenty data points each. We look at the standard deviation and if the data do not fit, we rerun it. We typically look for outliers based on the standard deviation and base our reports on multiple tests.

| Related Content: FAQ – Cable Pulling, Lubrication, and Tension |

Please comment on some of the challenges that you’ve encountered in laboratory friction testing

Ron: We have to adapt when faced with some samples. For example, we’ve had to make accommodation for some really large cables and conduits. Big utility jobs can use cables as large as seven inches (175 mm) in diameter, going through conduits ranging from four to twelve inches (100 to 300 mm).

Also, while numbers in the lab can vary, they do so even more in the field. In the lab we generate numbers in consistent and ideal conditions. But many things in the field can change the laboratory-generated friction coefficient number. The conduits may be dirty, for example. It may be a very warm day, causing the cable jackets to become sticky. Or, it can be very cold, making the jackets stiff and harder to bend around corners.

Sheri: Before testing, you really don’t know what to expect; something may feel slippery, but the test results show something different. We sometimes see interesting materials–some with seams, holes, corrugation, or ribbing. As we enter more international markets, we encounter new materials and manufacturing processes for the first time. We actually welcome new and different materials and the opportunity to expand our knowledge base. They help us develop solutions for any conditions that may be encountered.

What unusual cases have you seen while using the friction table?

Ron: The most unusual cases may be those where customers want optimal friction coefficients in existing conduits that have been in the ground a long time. Existing conduits, often made of concrete or tiles, can crack or break. Some conduits are more than a hundred years old.

Sheri: Replacing a conduit can be very expensive, so it’s a good idea to use an existing conduit, if possible. Also, today’s urban underground landscape is crowded. It can be difficult to find space for new conduits, and hard to remove old ones.

| Related Content: Measuring Cable Pulling Friction with a Reel Test |

Ron: We often work with large utilities whose projects can be interesting. There may be difficult cable pulls; for example, long pulls or pulls with very large cables. Knowing what to expect is important, and our customers like to avoid surprises. We test the cables and conduits for large jobs as part of the planning process. Plus, a good installation design that specifies optimal lube choice can reduce splices.

Polywater’s commitment to collaborative partnerships has resulted in the company’s reputation for outstanding customer service. How did this customer focus develop?

Sheri: We wanted to position Polywater as a technical leader. Our early focus was to approach cable manufacturers, and we had many one-on-one conversations with cable applications engineers and end users. Cable is the most expensive part of a system, and manufacturers don’t want their cables damaged during installation. Since our goal is to help customers succeed, we like to help plan projects and to also provide installation support.

As industry awareness of our friction table and knowledge base grew, cable manufacturers and end users began approaching us with questions and new samples for testing. This helped grow our database further, allowing a solid understanding of how our lubricants can minimize friction and maximize performance in cable pulls.

Ron: Manufacturers often ask which lube to use for the lowest friction. They also want information on compatibility with their cables. Our ability to answer these questions reliably over time has helped build the reputation.

| Related Content: Coefficient of Friction in Cable Pulling — Part 1 |

What are some of the trends that will challenge the friction table in the near future?

Sheri: New technologies and materials are always being explored. There is a lot of interest now in fire-retardant cable jackets. We’ve seen new CPE and LSZH jacket blends. We see different conduit types too. Manufacturers continue to look at specialty blends, such as fusible PVC or special fiberglass blends. We welcome cable and conduit samples for testing. Our preferences are to receive cables at least 2 inches (50.8 mm) in diameter and conduits 4 inches (101.6 mm) or larger.

More background on Polywater’s friction measurement + project planning support

Polywater is known for innovative product development in the electrical, utility, and telecommunications industries where construction and maintenance challenges demand fast and effective solutions. Through years of research and testing, the company has acquired extensive expertise, compiled robust laboratory and field data, and developed tools for customers that help ensure reliable and cost-effective project execution.