The Compelling Logic of Presaturated Cleaning Wipes

Solvent-saturated towelettes offer advantages over bulk packages such as totes, drums, pails, jugs, bottles, or aerosols. The benefits fall into three general categories: control, safety, and convenience. Presaturated towels reduce waste, speed drying time, promote proper cleaning techniques, and protect critical components.

An Analysis of Solvent Use in the Electrical & Communications Industries

For industrial cleaning, solvent-saturated towelettes prepackaged in pouches, tins, or canisters offer advantages over bulk packages such as totes, drums, pails, jugs, bottles, or aerosols. The benefits fall into three general categories: control, safety, and convenience.

Markets & Applications

Industrial cleaning is a broad topic, and while the points made here likely apply in many industries, our focus is in the electrical and communication trades where solvent is routinely used in significant volume for applications such as electrical cable termination, fiber optic splicing, hot stick and other live line tool cleaning and maintenance, surface preparation for conduit sealing and transformer leak repair, gas pipe fusion, hand and tool cleaning, and a host of others.

| Find the Industrial Cleaning Product for Your Needs |

Package Design

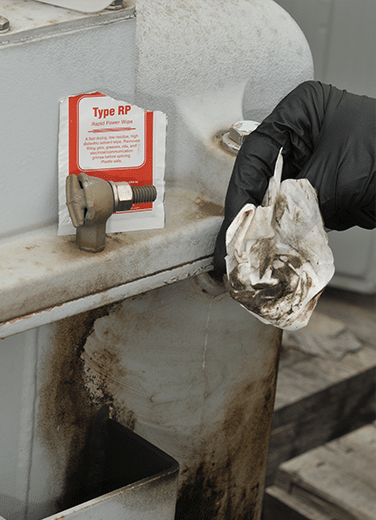

In these saturated towelette packages, the towel material itself is a part of the product design. Towels are chosen for properties such as absorbance (or release), strength, texture, and low-linting character. For example, very specific non-linting, non-tearing towels are required for fiber optic splicing and connector cleaning, or semi-conductive cable splicing. These towels must not contain chemicals (such as binding adhesives) that might dissolve in the solvent of choice and be redeposited on a cable, compromising a splice. A towel may contain small apertures or holes to collect grease and grimes. It may have a smooth texture for hard surface cleaning – or a textured surface to add a “scrubbing” function.

In these saturated towelette packages, the towel material itself is a part of the product design. Towels are chosen for properties such as absorbance (or release), strength, texture, and low-linting character. For example, very specific non-linting, non-tearing towels are required for fiber optic splicing and connector cleaning, or semi-conductive cable splicing. These towels must not contain chemicals (such as binding adhesives) that might dissolve in the solvent of choice and be redeposited on a cable, compromising a splice. A towel may contain small apertures or holes to collect grease and grimes. It may have a smooth texture for hard surface cleaning – or a textured surface to add a “scrubbing” function.

Presaturated, high-quality towel materials proven suitable for a task offer perfectly matched solvent quantities and towel counts, eliminating separate sourcing or storage. Work never halts due to too few wipes. Clean wipes are always available. This eliminates the use of dirty rags or inappropriate wipes that may reapply grime onto a “cleaned” surface or towels that may tear or lint or fail to absorb the contaminant at all. The size and saturation capacity of the towel can also be matched specifically to the intended end use.

Control

Presaturated towel packages ensure that minimal solvent is used. It eliminates solvent waste. A small amount of solvent often goes a long way. The use of presaturated towels control how much solvent is used and support proper cleaning procedures.

Using bulk packages to directly spray or immerse parts allows excess solvent to puddle in openings and remain in contact with surfaces too long. Excess solvent may be unintentionally sprayed or dripped onto nearby parts and materials. A small quantity of solvent briefly contacting a surface can reduce potential damage to an acceptable level. Minimal solvent should be used because soaking can swell or degrade highly sensitive rubbers and plastics, shortening component life expectancy.

A towel with limited saturation is an effective way to clean with slow-drying solvents. These types of cleaners may require a drying towel to speed evaporation. Lightly saturated wipes help the process. Presaturated towels reduce waste, speed drying time, promote proper cleaning techniques, and protect critical components from excess solvent exposure. Some solvents are hygroscopic, absorbing moisture from the air that potentially renders their use ineffective or harmful. The wipe package ensures the solvent does not absorb moisture and other contaminants from general handling.

Safety

Choosing a solvent is ultimately a balancing act of risk trade-offs: the positive performance specific to the task versus the negative consequences to personnel, infrastructure, and environment. Packaging plays a surprisingly significant role in this choice.

| Related Content: The Role of Specialty Cleaners in PPE Safety: Q&A with Randy Barnett, NFPA Certified Electrical Safety Professional (CESCP) |

There is obviously a large selection of available solvents with differing levels of risk. But regardless of the formulation, all solvents are chemicals, and every chemical has risk potential. Even water is corrosive on certain materials and is the last thing wanted near energized cables and equipment or the tools and personal protective gear used to service them. Every chemical should be assessed for risk potential.

Bulk solvents do not fare well in our risk assessment. They elevate hazmat concerns. They spill and splash, causing skin and eye damage ranging from mere irritation to permanent scarring and blindness. Many are combustible or flammable with low flash points, having fueled countless fires through the years. They carry varying levels of toxicity if consumed. Some are carcinogenic.

However, a worker’s primary exposure to solvents is via inhalation. Evaporation forms vapor concentrations in an air space. Excess solvent poured from bulk packages quickly increases vapor loading. Aerosols atomize solvents, instantly injecting large quantities of solvent vapor into a confined space. Health effects can range from short-term illness and mental fog to long-term disability, reproductive damage, disease, and even death. Inhalation guidance is measured as occupational exposure limits (OEL) in weight per air volume or parts per million (ppm). Limiting solvent use reduces vapor concentration so that these limits are not exceeded.

| Related Content: Polywater PEL-PAC® System |

Bulk cleaners are inherently more hazardous than saturated towelettes. Wipes with small, carefully measured quantities of solvent are the best way to control vapor. By design, they eliminate most spill, splash, and ingestion hazards. The smaller fuel quantity on individual wipes greatly lowers fire risk, even with a low flash point solvent. If a wipe ignites, there simply isn’t enough fuel for a larger conflagration.

Wipe packages reduce or eliminate accidental release into the environment. These packages reduce volatile organic compounds (VOC) released into the air and reduce the generation of greenhouse gases. Elimination of a spill and release hazard reduces regulatory reporting requirements. Proper storage, handling, and labeling are other aspects of regulatory compliance with potential fines for noncompliance. Labels can fall off, fade, or wash out over time on repetitive-use bulk packages.

| Related Content: Video: Live-Line Equipment & PPE Cleaning Solutions |

Saturated wipes don’t cause regulatory requirements to magically disappear, but they do substantially ease compliance. Each one-and-done wipe is always properly labeled, and the lower solvent quantities help maintain exposures below prescribed limits.

Safety and compliance naturally extend to storage and disposal. Warehousing bulk solvents may require climate control and/or containment areas, including spill basins, explosion-proof walls for flammable drums, or chain link cages for aerosols. Training and care are needed to avoid forklifts piercing drums and totes. Proper grounding may be necessary to avoid static discharge when transferring solvent to smaller containers. Inadequate packaging or its maintenance often leads to inventory loss through evaporation or degradation.

| Find the Saturated Wipe Needed for Your Project |

Saturated wipes change the solvent disposal paradigm. The package is opened. The solvent is used for its purpose. Any residual volatile material simply evaporates. What’s left is a dry towel that is usually legal to discard via standard disposal methods.

Convenience

Bulk solvent packages are too … bulky. They don’t fit easily in worker tool belts or pockets, or in service truck glove boxes or tool bins. Depending on what purchasing departments make available, workers may have to tote a heavy container to a worksite, in and out of a vault, or up and down a pole just to apply a small amount of solvent. Or they may try pouring the lesser needed amount into a small container, wasting time, and risking spills.

Bulk solvent packages are too … bulky. They don’t fit easily in worker tool belts or pockets, or in service truck glove boxes or tool bins. Depending on what purchasing departments make available, workers may have to tote a heavy container to a worksite, in and out of a vault, or up and down a pole just to apply a small amount of solvent. Or they may try pouring the lesser needed amount into a small container, wasting time, and risking spills.

Alternatively, a worker can stow the ideal number of saturated wipes in a pocket or tool bag and perform the onsite task in one easy trip. Customized kits can include dry towels and abrasive cloth, delivering a bundled supply of all items needed for a specific job, such as high-voltage splice termination.

Bulk packages are inefficient because labor costs more than solvent. Employees must tote heavy containers, source separate towels, and transfer potentially hazardous liquids. Working with bulk solvents is labor-intensive and dangerous. The mass production of lightweight, ergonomic, presaturated wipes by a manufacturer easily delivers the right combo of solvent and wipe to a cleaning site far more efficiently than utility or contractor organizations can accomplish on their own.

Economics 101

Bulk solvents may seem like a cost savings when the purchase order is issued. The key is that the mere purchase price of solvent is far from the only cost-related consideration. Solvent-saturated towelettes prepacked in foil pouches, tins, or canisters carry higher upfront prices but save money for the user in numerous other ways – more than enough to offset their premium price differential. The convenience of this packaging increases productivity and reduces the cost of labor. Sourcing and inventory are more efficient. There are fewer storage, shipping, and disposal considerations. Use of presaturated towelette packaging reduces regulatory oversight and risk.

| Related Content: Cleaning Rubber Goods for Safety |

Summary

Solvent purchase decisions should be based on a “whole picture” approach. A bulk package may appear suitable and less expensive, but is it so in the long run when all factors are considered? Solvents are highly regulated chemicals with a wide range of compatibility, safety, environmental, transportation, storage, compliance, disposal, liability, and labor implications, each one of which adds complexity and cost to a seemingly mundane supply item. While not necessarily eliminating such risks, in many cases the use of individually packaged presaturated solvent wipes is the single most responsible and effective way to significantly mitigate solvent exposure.