The Aging of Power Transformers

An integrated approach to assessing the factors that age transformers.

Key Takeaways

Learn the factors that contribute to transformer aging, see an integrated approach to assessing all of these factors, and help increase your ability to manage aging transformers.

To counter the negative consequences of the aging behavior of power transformers, users need to optimize the operation of their transformer populations from both a technical and a commercial point of view. This is a complex issue with no definitive answers. Aging refers to the natural degradation of the insulation system that consists of traditional, solid components like paper, press board, and plywood, and fluids such as insulating mineral oil. Of these, the solid insulating materials are most important as they cannot be replaced without completely rebuilding the transformer. This means users need to understand the aging processes of these materials to make a viable assessment of the general and remaining service life of transformers.

Transformer design and technology have undergone significant changes over the past 40 years. This makes it more difficult to assess how a transformer will age because aging will depend on the behavior of new materials and alternative insulating fluids. Nevertheless, existing transformer fleets still comprise systems insulated with traditional materials such as cellulose and mineral oil. Users also must assume that “standardized” assessments (e.g., Loading Guides in IEC and IEEE) are, by their nature, unreliable. These guides do not consider specific transformer design, materials or operating modes. In this sense, there is no such thing as the ideal “transformer.”

Understanding the aging behavior of these materials alone is not enough to determine a specific transformer’s condition. The insulating materials mentioned above all play a factor. There are more influences to consider. These influences include aging accelerators, transformer design, and DGA history. Adding a full range of factors makes assessing how a given transformer is aging even more complex and requires an integrated approach. Any method based on a single value, e.g., the degree of depolymerization, is of little use, particularly if that value is obtained from furan analysis.

I will walk you through an integrated approach that will help evaluate all of the following: assessing individual factors, the accelerators, the operating conditions, and the influence of different transformer designs.

| Related Content: Mapping Transformer Populations |

Aging Profile

The literature often assumes that aging is a linear process. However, this contradicts actual experience in the field, which has shown that aging is actually non-linear. The aging process is driven by a number of accelerators that are mutually exponentiating.

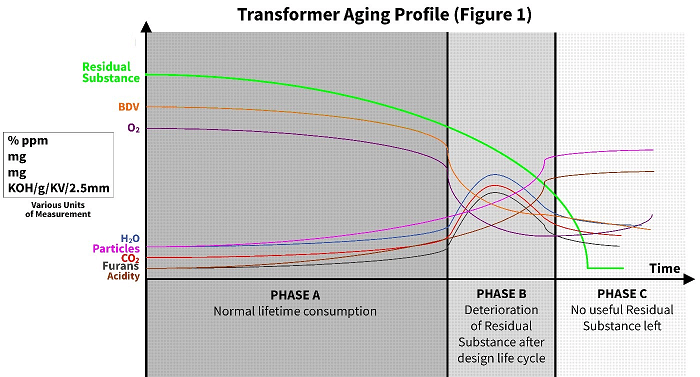

The graph below illustrates this non-linear process:

The graph shows the trajectories of various chemical and physical phenomena generated as the transformer ages. The key concept is shown in the diagram’s green line, which represents what may be called the residual substance. This parabolic trajectory appears time and time again in transformer aging assessments and negates the presumption of a linear aging process.

Replacing the term “remaining lifetime” with “residual substance” can be useful. Lifetime is relative and depends on the conditions of service and other factors. Residual substance is similar to the content of water in a bottle. It may be consumed quickly, slowly, or even actively conserved. Apply this principal to each transformer to optimize its lifetime.

Transformers are the “sneakiest” assets in a plant. Once a transformer enters the “C” range (Figure 1), it may not fail at all. Many cases exist where transformers remained in operation for several years after entering this end-of-life (EOL) state. However, once a transformer has reached this stage, its future performance may no longer be reliably estimated.

From a responsible operator’s point-of-view, the transformer is now beyond viable and calculable. At this point, it is a “gamble” where every extra day is a kind of “bonus.” Plenty of operators take this bet, and under certain conditions, this gamble may even be considered appropriate. However, the overall risk should remain a calculable risk, including the strong chance of fire in the event of catastrophic failure. At this stage, it’s important to consistently monitor a transformer.

Aging Rates

Transformers age in different ways and at different rates. This is due to the interaction of various aging accelerators.

Accelerators

- Temperature—As with all chemical processes, the aging process in the oil/cellulosic system is accelerated by temperature. However, this effect is non-linear. Below an oil temperature of 50°C, there is virtually no thermally-driven aging.

- Oxygen—Oxygen does its job in the same manner as everywhere else, oxidizing both the organic insulation materials and the oil.

- Acid—The chemical interaction between the cellulose materials, oil and oxygen, produces various organic acids, which in turn, accelerate the degradation of the cellulose.

- Water— Recently, much has been written about the role of water as an aging accelerator. It is also true that water is produced during cellulose degradation. However, the major portion of the water comes from outside the transformer, mostly through leaks caused by the differences in relative humidity gradient inside and outside of the transformer tank.

In future articles, I will cover how to deal with these aging accelerators and how the service life of the transformer can be improved with appropriate measures.

| Related Content: Transformer Leak Repair Story from Polywater® |

Transformer Design

A transformer’s design has a major influence on its service life and on the formation and effect of the aging accelerators. An unfavorable design can lead to an EOL condition much faster than the day-to-day impact accelerators may have on the aging process.

Differences in design may also lead to differences in aging behavior. The transformer’s design therefore must be considered when assessing its condition. Two transformers with identical name plate data, but made by different manufacturers, will rarely exhibit identical aging behavior. Most likely, their aging behavior will be vastly different.

Montsinger Rule

The correlation or rule established by Montsinger states that every temperature increase of 6°C leads to a doubling of the aging rate of machinery. For practical purposes, one can safely use a 10°C increase. Also, there is virtually no thermally-driven aging below the temperature of 50°C. However, individual components of the system may well exceed this temperature. This is where accelerated aging may well occur. Indicators that confirm this effect can usually be found in the DGA. In any case, experience has shown that the Montsinger Rule is both realistic and reliable.

| Related Content: Mapping as Risk and Cost Assessment Methodology |

Summary and Outlook

This article addresses only the aging behavior of classic transformers with oil/cellulose insulation systems. Such transformers still make up the majority of transformer populations around the world. Also, there are very old units in this group, some of which have been in operation for 50 years or more. This presents a dilemma to the operator, i.e., to determine whether these older units are still safe to operate and the best way to approach fleet replacement.

What is certain is that age alone is not a criterion for replacement. This is evident from the different conditions of old transformers, which can range from EOL or “Zero” remaining life, to easily another 20 years of life.

Aged and overaged transformer population cohorts require extensive mapping and an integrated assessment approach to ensure that they are properly managed. What should be avoided is phasing out stable and usable units simply because of their age, while unexpectedly losing younger, inadequately designed transformers. This would impair the reliability of energy supply while scarce reinvestment funds are spent in the wrong place.

In my next article, I will discuss how temperature and water influence the aging of transformers.

| Related Content: How Oxygen and Acids Influence the Aging of Transformers |

Have any questions?

| For solutions on repairing and maintaining transformers, visit: Polywater® PowerPatch® Transformer Leak Repair System |