Keeping Rodents Out of Critical Infrastructure

Keep rodents out of your electric and communications cabling by learning key signs of infestation and investing in the right sealant.

How Do You Avoid Downtime and Expensive Repairs Caused by Rodents?

You may not see rodents enter your cabling structure or utility enclosure, but you will easily detect evidence of their presence. Rodents chew through cable and damage equipment. They leave a mess and spread disease. The damage can cause outages leading to service interruption and time-consuming damage tracking and repair.

Rodents are small, nocturnal animals that are not always noticed immediately. They are voracious chewers and a common problem. Sealing cable penetrations to prevent intrusion is best practice and should be considered standard procedure. By sealing the opening, you create a barrier. This stops airflow and limits warmth or odors that might entice the rodent to enter the enclosure. A good sealant is a good rodent deterrent.

| Learn more about Urethane Safety: MDI Monitoring on Polywater® Foaming and Non-foaming Urethane Products |

What Is a Rodent Deterrent?

Repellents are something that repels or drives off rodents. This is often done with a strong, offensive odor. This is not a feasible approach for most utility structures because it will drive off human workers and occupants as well. A more practical approach is to use a good rodent deterrent. A deterrent is something that either deters, prevents, or inhibits the pest from entering. In the case of a rodent deterrent, the rodent may come into contact with the material but then become thwarted either by the difficulty of entry or by distaste and discomfort from the first bite.

What Is a Good Barrier for Preventing Rodent Entry into Critical Infrastructure?

Chemical duct seals create a barrier and act as a deterrent. It is important that the seal is strong and durable to prevent animal entry. In the case of chemical duct blocks, a medium density, closed-cell structure can be effective. One-part hardware store foams are commonly used and are easy for rodents to destroy. Rodents will use this soft foam as nesting material. A medium density foam is measured between 4 to 8 lbs/ft3 (17 to 34 grams/cm3). Soft putties are also ineffective barriers. Closed-cell sealants are rigid and will not compress. Good seal installation will create a more durable barrier. It is important that the rodent cannot gain purchase to take a bite or start chewing into the material. When installing seals, do not leave divots or edges that may be easy for small animals to bite.

High performance duct seals can be further enhanced with the addition of chemical agents that are distasteful to rodents and other animals. Polywater® FST™ now has a bittering agent added to its formula. Additives should never change the product performance. They should not add toxicity or be unpleasant for the installer and people that work around the finished seal. Enhanced sealants should be watertight, gastight and still pass hydrostatic (water) and air tests.

A strong sealant with rodent deterrent additive acts as a double barrier against rodents.

| View FST Application Instructions |

How Do You Test the Efficacy of Rodent Deterrents?

Duct sealants were tested for their ability to deter rodents. In this testing, barrier samples were placed inside a test system and exposed to feeder rats. The barriers were then monitored for evidence of chewing and seal damage. The test system was designed with water available and a comfortable layer of aspen shavings that were cleaned between replicates. A tunnel divided the introduction side and the food source. The feeder rats were placed into the test system to acclimate and find the food source. After acclimation, the tunnel was closed off using a 5/8-inch (16 mm) barrier of the duct sealant. Each seal had a small hole placed in the center. Note that duct seals are typically installed in a 3-inch (75-mm) depth, so this is about one-fifth the typically installed thickness. Observation includes weight loss due to chewing and whether the rat chewed through the system.

There are a few key steps in this test:

- A mixed selection of adult feeder rats, both male and female

- Acclimating the rats so that they are aware of the food source

- Creation of a starter hole to allow rat teeth to gain purchase

- Test replicates – multiple tests per seal type

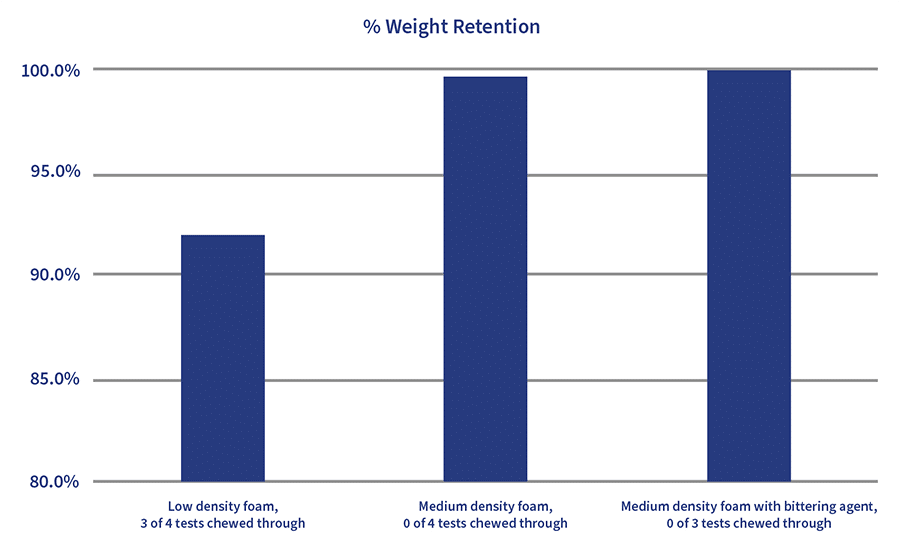

In this test a lower density foam, a higher density foam, and the higher density foam with a bittering agent were tested.

Chart 1

Test results show that the denser the foam, the more resistant it is to chewing by the rodents. The bittering agent is an added insurance against rodent intrusion. This testing shows that duct seals are a rodent and animal deterrent.

What Needs to Be Sealed to Avoid Damage from Rodents?

Cable sealing methods are a design level decision that should be specified as part of the project phase. One-part hardware store foams and duct putty are not adequate solutions. These materials will not stop rodents from entering critical infrastructure. To protect the underground components in an electrified building, utility infrastructure, or cabling plant, seal all conduit and risers at least to the second story. These can become rat raceways. Seal all cabinets, enclosures, and any wall penetration. Use a good barrier product as part of the project design.