Investing in Maximum Fiber Optic Cable Installation Longevity

Discover how various Polywater® products can be used to protect fiber optic cable longevity both during and after installation.

Meeting the High-Speed Demand at a Fast Pace

Communication companies are working at full capacity to install billions of kilometers of fiber optic (FO) cables worldwide to address demand for increased high-speed internet. This vital work is accomplished in a highly competitive landscape, where companies race against each other to expand markets by building out underserviced (remote or rural) regions or by upgrading networks in densely populated areas. These efforts amount to a huge investment by communication companies, businesses, and municipalities. In this context, success is measured by the ability to reduce installation time and cost to get the network up and running as quickly as possible.

How are communication companies protecting their FO network investment to ensure the longevity of their installation?

Protecting a FO network investment and ensuring its longevity begins at installation. Implementing the best installation practices helps reduce downtime and maintenance costs over the life of the network. This includes safe handling practices of the cable at installation and building a closed and protected system from the intrusion of environmental elements that could disrupt service.

Protecting the Network at Installation

Fiber optic cables can remain in operation for decades if properly handled before and during installation. How they are installed can have a significant impact on the operational reliability, longevity, and maintenance of the system. Cable manufacturers provide guidelines for how their cables should be handled and installed, but additional safety measures can be taken during the installation. No matter which installation method is used — whether pulling, jetting, or blowing the FO cable through the conduit — it is vital to safeguard the cable and conduit against damage due to friction, tension, and improper lubricating compounds. The use of high-performance cable lubricants reduces the coefficient of friction, allowing the cable to safely travel longer distances.

Once the FO cable is installed in the conduit, the system must be closed and protected from intrusion. Industry guidelines and standards (ITU-T L.92, ITU-T L.162, TIA-758-B Standard 5.4.2.3, and BICSI-TDMM, Telecommunications Distribution Methods Manual) cover how to seal ducts and conduits to prevent water, air, gas, and vermin from traveling through the conduit network.

| Related Content: Frequently Asked Questions Cable Pulling Lubrication and Tension |

When should fiber optic cable-in-conduit networks be sealed?

The most practical time to seal the conduit is immediately after the cable is installed. Crews are already present, and sealing after cable installation ensures optimal system protection. Depending on the environmental conditions and performance requirements, crews can use mechanical seals or specially formulated two-part sealants to quickly seal the network. These types of sealants provide a long-lasting watertight, airtight, and rodent-secure seals, that are re-enterable for future network upgrades or maintenance. Unfortunately, this critical step is sometimes deprioritized at installation due to cost and project deadlines.

What is the impact of not sealing the conduit after cable installation?

Any opening in the conduit system that is not sealed becomes a vulnerability point that can lead to a potential service outage. Examples include conduits that are not sealed properly, conduits that are sealed with the wrong type of sealant, conduits ends that are left unsealed after cable installation, non-watertight couplings, or cracks or holes in the conduit. In underground installations, the most common intrusion is water. If the conduit is connected to a building entrance, water can seep in through the conduit and cause damage to the structure or equipment. In situations where conduit is buried above the frost line or under bridge crossings, it is susceptible to freezing temperatures. Water in the system can turn into ice and seriously damage the FO cable. Ice formation leads to a host of issues, including signal attenuation, loss, or even network outages. A specialized solution to prevent ice formation is an antifreeze cable gel. This can be installed along with conduit sealants to harden the system.

| Related Content: Antifreeze Cable Gel: What It Is and What You Need to Know |

If conduits are left unsealed, another unwanted network intrusion is rodent presence. They search for food and warm, dark places to nest, such as handholes, pedestals, or network cabinets. They are notorious for chewing through cable jackets, damaging cables, and wreaking havoc on a network, not to mention being a health hazard to maintenance crews. Sealing conduits and pedestals ensures a closed system and keeps rodents out of the network. If the system is not sealed and rodents have nested in it, their presence invites the next critter up the food chain: snakes, which are natural predators to small rodents. These reptiles not only present a danger to the network but also to maintenance crews who may encounter them during an inspection. Some types of expanding foam sealants include a specialized bittering agent that acts as a deterrent for rodents. The airtight seal also prevents the smell of any potential food source from traveling through the conduit network, thus further deterring rodents along with their natural predators.

The Economic Advantage of Sealing Conduits at Cable Installation

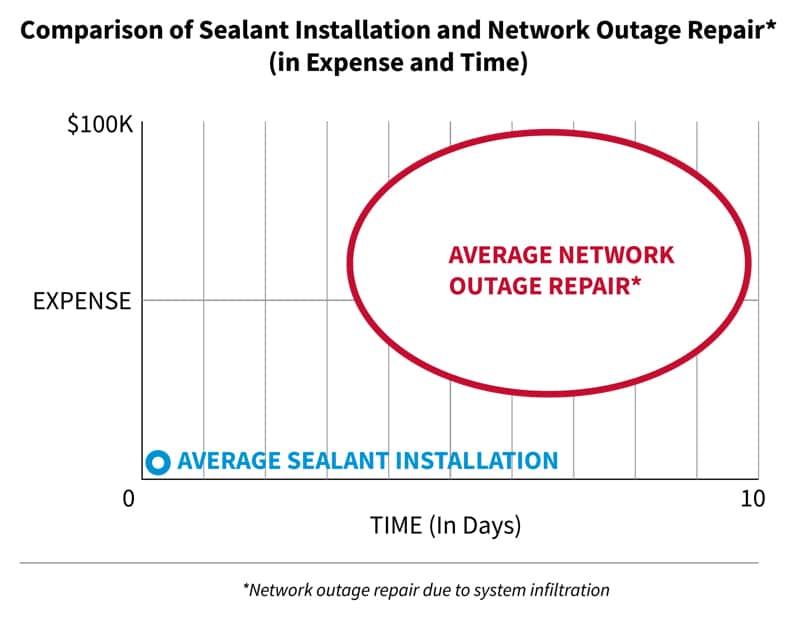

Installing conduit and pedestal sealants immediately following FO cable installation reduces the risk of future issues related to network downtime and potential repairs. Consider this network outage scenario caused by rodent infestation due to an unsealed system. Resolving this issue can be a long and costly process. Starting from the initial service call for the outage, a technical service person is dispatched to troubleshoot the situation. Once they have identified the problem, and it requires construction or replacement, the identification of buried utilities will be needed before the project can begin. Then there are extermination efforts, replacement materials, potential permits or traffic control, cable installation, splicing, and any potential restoration related to construction efforts that will follow. All of this is going on while the network is down. Then in the end, once the repair is complete, a sealant is installed to prevent a future issue. The irony in this scenario speaks for itself. Unfortunately, for some network owners this is an all too familiar situation.

When you factor in all the components that go into solving a network outage issue, the economic benefits of adopting a process where sealants are installed in tandem with cable far out way any objection. In this respect, conduit and pedestal sealants are a low-cost insurance to prevent network intrusion that could cause serious damage—requiring both time and money to solve. Companies protect their network investment by shifting from a “cost of installation” mindset to a “total cost of ownership” mindset, to have the ultimate peace of mind.

Conclusion

At the pace at which companies are installing FO cables in conduits, installing sealants in tandem with antifreeze cable gel can greatly contribute to optimal network performance and reduce costs associated with service calls or network outages. Protecting a huge investment like a FO cable network installation seems simple enough on paper; however, with process changes in place, the longevity of the network can be ensured.

Are you looking for more information about how to improve the longevity of your fiber optic network investment? Get in touch with Polywater to discuss any questions or to get help finding solutions to your unique fiber optic cable installation challenges.