Dispelling Myths About Sealing Conduits and Ducts

Sealing conduits and ducts around cables, wires, and pipes is essential for system hardening, code compliance, or meeting network owner requirements. When no specific sealant is specified on a construction project, the choice is left to installers or contractors. However, if an improper sealant is used it may fail under environmental stress. This can allow water, gas, rodents, and other intrusions to infiltrate the system and damage critical assets.

Despite the importance of proper sealing, confusion and myths about materials and installation persist, leading to misconceptions and incorrect practices. Here, Polywater® addresses five common myths about conduit sealants with insights from research and industry expertise.

Myth 1: “Duct Putty works well to seal around a cable in a conduit.”

Despite the common usage of duct putty to seal around cables, conduits, and pipes, it is not intended for this application. Duct putty is most suited for ducted HVAC systems to block air movement, dust, noise, and low levels of moisture, and in certain plumbing and refrigeration applications. Duct putty is pliable and distorts with temperature elevation and movement. This can create voids or openings within the annular space of the conduit that allows undesirable intrusions like water, gas, and rodents into the system.

Reality: Duct putty is not suitable as a long-term conduit sealant to harden and protect underground electrical and telecommunications systems. Its qualities do not provide the performance needed to secure mission critical systems and networks effectively from unwanted and harmful intrusions. It is best to use a sealant that is engineered specifically for conduits and can withstand the rigors of underground environments.

| Related Content: Why Duct Putty Fails to Seal Conduits |

Myth 2: “All expanding spray foam sealants work the same way to seal conduits.”

There are many different types of spray foam sealant products available on the market. Each variety is designed for specific applications and tasks. While they may deploy in a comparable way or even look the same when they come out of the container, they have vastly different chemistry, performance characteristics, and intentions for use.

Reality: Not all spray foam sealants are the same. Common hardware store spray foam sealants are created to fill gaps and cracks in construction projects, such as in and around door and window jams to seal out air. When these spray foam sealants are used in a duct or conduit they do not cure properly and have significant performance limitations when confronted with water head pressure and animal intrusion. It is best to only use a spray foam sealant that is designed specifically for sealing underground conduits or ducts to create seals that will withstand the environmental conditions and endure.

| Related Content: FAQs on Expanding Foam Duct and Conduit Sealants |

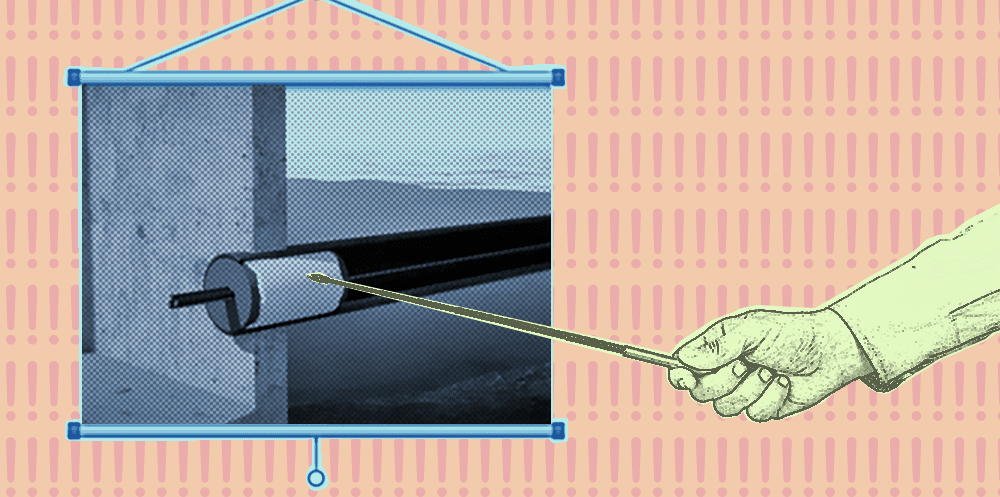

Myth 3: “Only mechanical seals will keep significant water head pressure out of conduits.”

While most mechanical seal systems can protect against water from entering a conduit or duct network, they are not the only sealant option to withstand significant water head pressure.

Reality: Engineered expanding foam conduit sealants, like Polywater® FST™ and Polywater® AFT™, can guard against significant water head pressures. Polywater® FST™ holds 22 feet (6.7 m) of continuous water head pressure and up to 90-foot (27 m) surges. Polywater® AFT™ is also an excellent water-blocking sealant with the ability to hold back 11 feet (3.4 m) of continuous water head pressure. Depending on the performance requirement or situation, specifying an engineered expanding foam conduit sealant can have substantial cost and labor savings on a project when compared to mechanical seals.

| Related Content: Duct Seal Prevent Ruinous Water Damage |

Myth 4: “Rodents and small animals can chew through all foam sealants.”

Rodents and small animals are often drawn to spaces like junction boxes, utility enclosures, pedestals, riser poles, and u-guards where conduits and ducts are attached. They are lured in for warmth, protection, and food. If a duct or conduit is not properly sealed, air movement can carry smells that entice the animal to infiltrate the system. Additionally, the heat generated from energized cables and systems will allure them to enter an enclosure. Once inside the enclosure they may decide to burrow further into the system. If a foam sealant is present, they may or may not bite into it. This depends on if there is an air leak with a temperature differential and if there is a smell that attracts them.

Reality: A great sealant is great rodent prevention. If the seal is tight, rodents normally will not bother the seal because there is nothing present to make them think there is anything beyond the seal. Regardless, rodents and small animals may still bite into foam sealants. Certain expanding foam conduit and duct sealants, like Polywater® FST™, are formulated with bittering agents that block the animal from chewing because of the foul taste. These sealants are labeled as containing a rodent deterrent. These sealants add an additional layer of security to deter rodents.

| Related Content: Keeping Rodents Out of Critical Infrastructure |

Myth 5: “Installing sealants around a cable entry or in a conduit is too labor intensive.”

The proper installation of a conduit or duct sealant requires some level of effort. In most projects, sealants are installed around a cable entry after the cable has been installed or pulled through a duct. The act of sealing the duct is treated as a separate task from cable installation and often completed by a different team or crew. But the effort required to install a sealant depends on the type of sealant system.

Reality: Within the categories of expanding foam conduit sealants and mechanical seals, there are varying degrees of complexity required to professionally install a sealant. However, the more complex the seal is to install does not equate to it being a more durable or reliable seal. The human factor is also a big contributor. You can have the best sealant, but it can be installed improperly. Conduit sealant systems from Polywater are specifically engineered to be more practical for installers, with components that are simple to use and integrate with workflows. This makes installation less labor intensive per seal and helps mitigate human error. Other sealant systems on the market require many steps and multiple complicated components, often requiring more than one person to complete the installation. Certainly, it requires some work to install sealant systems. Yet, specifying a sealant that meets performance requirements and is quick and simple to install is the ideal option to alleviate labor concerns.

| Related Content: Polywater FST Duct Sealant Instructions for Use |

Understanding Conduit and Duct Sealants

As manufacturers continue to educate about proper sealant application to the electrical, communications, and waterworks trade segments, engineers and installers can better understand the materials and have confidence in using them. Dispelling these persisting myths about conduit and duct sealants can lead to safer systems and optimal sealant selection practices. By understanding what level of performance is required from a conduit sealant, based on environmental factors, sealant specification can be made more deliberate and purposeful, leading to the protection and resiliency of critical infrastructure and assets.

| Related Content: Is Meeting a Standard Enough—An Examination of Duct Sealing Code Compliance |