Cost Effective On-Site Leak Repair of Power Transformers

According to the World Bank, a billion people worldwide still live without electricity, and hundreds of millions more live with unreliable or expensive power. An important element to reliable access to affordable electricity is the consistent operation of the many power transformers in the power grid.

Key Takeaways

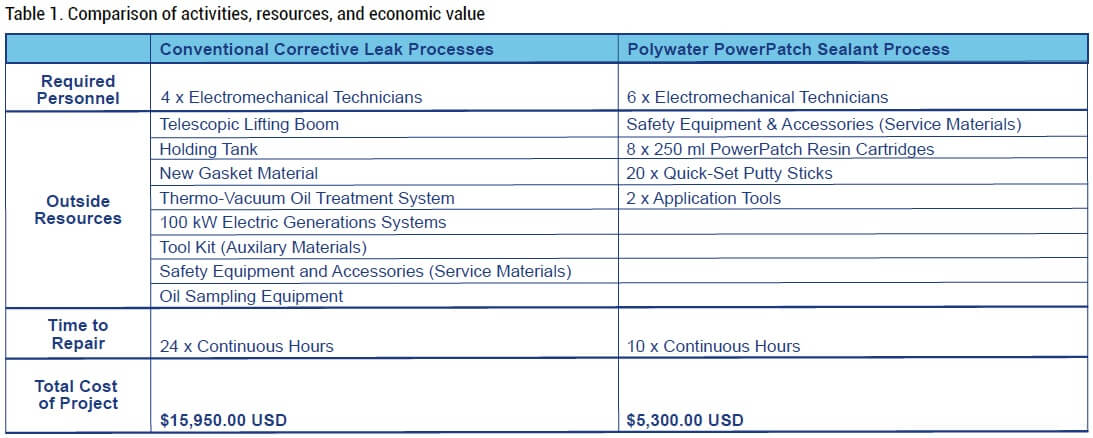

When the cost of the Polywater® PowerPatch® Sealant process is compared to the cost of the conventional approach, the savings are approximately three times greater.

Electrical energy generation and distribution have been essential factors in the economic development and progress in many regions of the world. Many countries are focused on expanding and maintaining their electrical grids to provide dependable and reliable energy to meet the growing energy needs. According to the World Bank, a billion people worldwide still live without electricity, and hundreds of millions more live with unreliable or expensive power. An important element to reliable access to affordable electricity is the consistent operation of the many power transformers in the power grid. Their performance in substations and switchyards is essential for a properly functioning grid. The supply of electricity through this network of power transformers depends on their continuous operation. One issue that impacts the continuity and quality of the electrical service supplied by power transformers is the leakage of dielectric oil used to dissipate the heat generated during their operation. Quick and cost-effective repair of transformer oil leaks ensures reliable performance of the electrical network. The use of innovative sealant technology from Polywater® for in-field repair of performance-degrading transformer oil leaks will be reviewed below. Compared to traditional repair processes, the use of Polywater sealant technology has proven many times to be a faster and more cost-effective oil leak remediation method.

Electrical energy generation and distribution have been essential factors in the economic development and progress in many regions of the world. Many countries are focused on expanding and maintaining their electrical grids to provide dependable and reliable energy to meet the growing energy needs. According to the World Bank, a billion people worldwide still live without electricity, and hundreds of millions more live with unreliable or expensive power. An important element to reliable access to affordable electricity is the consistent operation of the many power transformers in the power grid. Their performance in substations and switchyards is essential for a properly functioning grid. The supply of electricity through this network of power transformers depends on their continuous operation. One issue that impacts the continuity and quality of the electrical service supplied by power transformers is the leakage of dielectric oil used to dissipate the heat generated during their operation. Quick and cost-effective repair of transformer oil leaks ensures reliable performance of the electrical network. The use of innovative sealant technology from Polywater® for in-field repair of performance-degrading transformer oil leaks will be reviewed below. Compared to traditional repair processes, the use of Polywater sealant technology has proven many times to be a faster and more cost-effective oil leak remediation method.

| Related Content: Transformer Leak Repair Story from Polywater® |

Oil leaks are generated in a variety of ways, through pinholes, welding defects, worn gaskets and radiator cooling fin corrosion or rust. The loss of dielectric fluids from a power transformer has many deleterious effects. High temperatures within the transformer due to oil loss affect the quality and dependability of the supply of power. Additionally, high heat contributes to accelerated decomposition of the solid insulation which leads to accelerated aging of the transformer. Leaks also provide a gateway for atmospheric gases, such as oxygen and nitrogen, into the transformer. They degrade oil quality and further accelerate cellulosic depolymerization. Any oil leak, no matter how small, is an open pathway for moisture to enter the transformer. Water in a transformer reduces its useful life and puts at risk the coordinated operation of the transformer in the electrical grid. The reduction in the number and severity of transformer oil leaks is critical to improved grid performance and power quality.

Correcting problems caused by oil leaks can be very complicated, costly, and time-consuming. Often, conventional remediation processes require long shutdowns of power to the transformer, which reduce revenue generation while repairs are being made. Processes that minimize the time to repair/replace significantly lower the opportunity costs of lost service revenue. To better understand the financial impact of different corrective actions in the repair of power transformer leaks, we will assess examples where conventional corrective processes are compared to in-field sealant repair technologies. We compare traditional gasket replacement to gasket leak repair using Polywater’s PowerPatch® leak repair system and assess the time and cost needed for each process to stop an oil leak in the bell tank gasket. It will be assumed that the transformer is in proper functioning condition, but the nitrile gasket has failed. We start below with a description of the conventional process used to replace a leaking gasket of a power transformer at a power company in Lima, Perú.

Description and characteristics of a transformer gasket leak:

Electrical: 22 MVA – 60 / 13.8 kV – 192 5 / 920 4 A – group YNd11

Weights: Active parts 18,600 kg – oil 8,900 kg – tank 4,000 kg – total weight 37,100 kg

Defect: Oil leak from the main gasket between the tank and tank cover

Work required: Replacement of gasket between the main tank and tank cover

Equipment to be used in repair: 30 ton telescopic crane, holding tank with a minimum capacity of 3,000 l (2,600 kg), oil treatment system with a minimum oil treatment capacity of 5,000 l / h, power unit of 80 to 100 kW (in the event there is no energy source), tool kit, instruments, safety equipment, service materials, (gloves, insulated blankets, grounding cables), and auxiliary equipment (chain blocks, hoists)

Required personnel: 3 to 4 electro-mechanical technicians

Description of the work required to replace the gasket:

- Shut down energy to the transformer

- Verify that energy to the transformer has been shut down

- Place medium and high voltage grounding terminal blocks

- Disconnect input, output, and control cables

- Position telescopic crane for lifting the top of the transformer

- Transfer transformer oil to holding tank and to draw down oil level to 20 cm (7.9 in) below oil tank top

- Loosen 60 x top bolts of 1.58 mm (5/8 in) from the oil tank

- Connect rigging to lift the active part of the transformer

- Lift active part to 20 – 30 cm above the top of the tank to provide access to the gasket

- Remove original gasket material, clean the surface where the old gasket was positioned, and place the new gasket

- Lower active part of the transformer into the tank

- Place and adjust top bolts to the tank and remove the crane

- Treat dielectric fluid in the holding tank over two consecutive cycles to obtain a relative humidity of 5 ppm in the transformer oil

- Transfer oil from the lower valve of the transformer through the oil treatment system to the holding tank

- Treat oil in the transformer to obtain a relative humidity of 5 ppm of the transformer oil

- Take final sample and test dielectric fluid. Acceptable result: not less than 40 kV / 2 mm (ASTM D1816 for in-service oil).

- Reconnect input, output, and control cables

- Remove earthing cables and other extraneous materials from the transformer

- Allow settling time of at least 2 hours

- Purge Buchholz relay and high and medium tension insulators

- Reenergize the transformer

| Related Content: The Aging of Power Transformers |

The traditional replacement process described above is very time consuming and capital equipment intensive. It is estimated that this process would require at least 24 hours of continuous monitoring and the use of technically specialized auxiliary equipment. Alternatives to the process outlined above have been tried to reduce the time and cost of repairing a leaking gasket. A range of products, including sealants, have been used. These repair options do not effectively stop gasket leaks. Many of the products used were developed for other applications and not tested appropriately for the repair of persistent, dielectric fluid leaks through worn gaskets. Polywater’s PowerPatch Leak Repair System is designed for the repair of a wide variety of transformer leaks and has been used successfully in many countries around the world. The remediation of a gasket leak using PowerPatch is described below.

Polywater PowerPatch for in-field repair of active leaks

Polywater’s fast-curing, two-part resin sealant is designed for the temporary or permanent repair of transformer leaks. The PowerPatch Leak Repair System has been used successfully to contain and seal a wide range of active leaks encountered in the field. Once applied and cured, PowerPatch seals have exhibited superior strength against leaks of dielectric fluids and insulating gases such as SF6. When an active oil leak is found, immediate plans must be made to stop the leak in a fast, efficient, and cost-effective manner. As described above, achieving these objectives using conventional replacement processes is often difficult. Oil tank gasket leaks are time-consuming and costly to rectify with conventional methods. Replacing nitrile or cork gasket materials used to seal the main oil tank requires heavy equipment to lift the top and active part of the transformer to gain access to the gasket. Opening the tank exposes the transformer oil to moisture and atmospheric gases, which require oil treatment to reduce their deleterious effects. This is another time-consuming step in the conventional leak repair process and requires the use of costly oil treatment systems.

The PowerPatch Leak Repair System offers a safe and effective alternative to conventional gasket replacement. Instead of replacement, the PowerPatch system is used to seal the perimeter of the tank cover to stop active oil leakage. There is no need to lift the top off the tank, which limits exposure of the oil to the harmful effects of water and gases. The costs and time required for oil treatment also are eliminated when PowerPatch is used.

| Related Content: Mapping Transformer Populations |

Among the many features of PowerPatch, its high-pressure resistance is noteworthy. For example, its resistance to pressure when adhered to steel is over 13.7 bar (199 psi). PowerPatch also adheres strongly to other materials often found in transformer components such as copper, brass, and ceramic. The capacity of PowerPatch to resist high pressure allows its use on large oil-filled power transformers and in sealing leaks in SF6 insulated switchgear. Another valuable feature of PowerPatch is its high dielectric breakdown voltage. Similar to that of transformer oil, the use of Polywater’s PowerPatch minimizes the potential for partial discharge in the transformer.

Gasket leak sealing with PowerPatch

Following the above example of conventional methods to replace leaking gaskets, we will describe the application process to seal an actively leaking gasket between the top and the oil tank on the same trans-former using the PowerPatch system. Instead of replacing the entire gasket as done in the conventional process, we use PowerPatch to seal the perimeter of the oil tank. In addition, the nuts and bolts that secure the cover to the tank will be sealed to prevent oil from leaking through the bolt threads.

Necessary personnel: 5 – 6 electro-mechanical technicians

Description of the work to be performed to seal the gasket:

- Shut down energy to the transformer

- Verify that energy to the transformer has been shut down

- Disconnect input, output, and control cables

- Prepare the surface of the gasket perimeter and tank cover where the PowerPatch will be applied. This initial step is very important to create a tight seal. Proper preparation includes abrading surfaces with sandpaper, metal brush, or a rotating metal brush connected to an electric drill. Note that abrasion increases surface area to improve adhesion. Additional surface preparation includes cleaning to remove paint and any contamination or residue from the surface that may compromise strong adhesion.

- Apply quick-curing putty to stop actively leaking oil; apply the putty along the entire perimeter of the tank / tank cover; once putty is hardened, inspect the entire perimeter to verify that all leaking has stopped

- Perform secondary cleaning by abrading the surface and removing surface residue after application of the putty

- Apply the permanent sealing resin directly over the hardened putty along the tank’s perimeter and to the bolt heads and nuts

- After application of the permanent resin is complete, remove all safety equipment on or around the transformer

- Remove earthing cables and any other extraneous materials in and around the transformer

- Reenergize the transformer

| Related Content: How Oxygen and Acids Influence the Aging of Transformers |

We can see that the use of PowerPatch to seal a transformer oil tank gasket leak reduces the time required for the corrective process. In addition, PowerPatch offers positive economic benefits, which include savings from the sealing process itself, time and from the lower opportunity costs of service shutdown. A comparison of the savings and costs between the complete gasket replacement and leak sealing processes are shown in Table 1.

PowerPatch

The PowerPatch family of leak repair sealants allows for the safe and economical repair of oil and gas leaks in a variety of transformer and switchgear equipment. The multi-use PowerPatch cartridges (EPCT) are designed for repairs as small as pinholes in cooling radiator fins and valves and as large as oil tank main gasket repair. The application of the permanent resin described above can be applied with either 50 or 250 ml PowerPatch cartridges. The 50 ml cartridge is ideal for smaller repairs, while the 250 ml cartridge can be used for medium or larger repairs such as those found around flanges and bushings. The cartridges’ reusability minimizes resin waste to reduce repair costs. The two-part resin cartridges ensure accurate mixing of Parts A and B to ensure maximum adhesion and consistent working times.

Other PowerPatch packages are available for other types of transformer repairs. The EP package consists of two small containers of resin Parts A and B. They are mixed manually, after which the combined resin can be applied with a wooden spatula to irregularly shaped areas needing repair. Both EPCT and EP packages include a quick-setting putty stick for the repair of active oil leaks, as described in the leak repair process above. PowerPatch Slow Cure (EPSC) comes with 290 ml of Parts A and B and is used for large-area repairs. Its use is recommended for large, high-voltage transformers where the slower cure time of ESPC ensures sufficient working time for applying resin to the repair area.

Summary

The proper functioning of oil and SF6 insulated equipment, essential components of electrical grids around the world, is critical. The quick and cost-effective repair of power transformer leaks ensures reliable and high-quality electrical services to homes, businesses, and industries. Using versatile and innovative sealant technology from Polywater for on-site repair of oil leaks has been shown to lower both the cost and time required. The use of Polywater’s PowerPatch leak repair products reduces transformer shutdown time from 24 hours to 8 to 10 hours and also results in much lower costs. The costs of lifting cranes, oil treatment systems, and other equipment needed for on-site gasket replacement were over $10,000 higher than using the PowerPatch Leak Repair System.

Have any questions?

Originally published in Transformers Magazine, Volume 7, Issue 4, 2020