Why Does Duct Putty Fail to Seal Conduits?

Duct Putty is commonly used to seal electrical and communications duct worldwide, but falls seriously short of expectations. This paper examines those shortcomings and why the use of duct sealant can be problematic.

Duct putty is arguably the most common product used to seal electrical and telecommunications conduits worldwide. The product is cheap, safe, easy, and ubiquitous. It ostensibly allows cable installers to comply with industry codes mandating that conduits are sealed. Unfortunately, this seemingly ideal sealant too often falls short of expectations, resulting in expensive damage that far outweighs any perceived convenience or cost savings over high-performance, engineered sealing solutions. This article reviews duct putty and analyzes specifically why its use as a duct sealant can be problematic.

What Is Duct Putty?

Though formulations obviously vary by manufacturer, duct putty is typically a thick and pliable inert commodity made of clay and water. Variations include mastic or oil and wax blends. It can be easily worked by hand to form an infinite variety of shapes that are pressed into place to seal HVAC ductwork—thus its name as a duct putty. It is also commonly used in the refrigeration and plumbing trades. Uses in the electrical and communications markets include sealing around electrical boxes, flashings, junction boxes, pedestals, service mast entries, etc. It seals gaps and cracks and works well to reduce drafts, moisture, dust, insects, and noise. Many commercially available duct putties are UL approved.

Duct putty is not, however, an excellent conduit sealant. It is important to note that a UL mark does not make a product suitable for a purpose other than the one it’s designed or marketed for. In the case of duct putty, the UL mark is generally for sealing junction boxes, not conduit entrances containing electrical or communications cables. Despite this, duct putty is often recommended for and marketed as a conduit sealant. Certainly, it is frequently used as such. Specifiers and engineers should understand that this is problematic for reliable cable installations because duct putty fails as a long-term sealant solution.

| Related Content: Is Meeting a Standard Enough?—An Examination of Duct Sealing Code Compliance. |

The Mechanisms of Seal Failure

Application is one cause of failure. Putty comes with no instructions on how much to use or how to properly seal a conduit. It is very sticky and hard to manipulate. Even a rudimentary seal is difficult to craft. Too often, initial installation results in no seal at all.

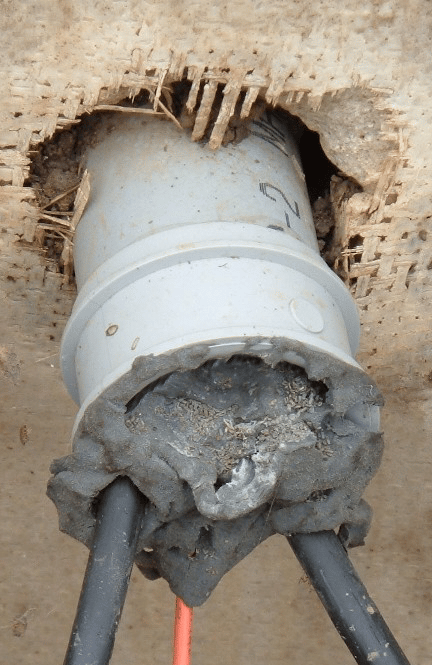

Even with adequate installation, when duct putty’s volatile content evaporates, it causes shrinkage that results in gaps. The shrinking sealant pulls away from conduit walls and/or cable jackets, opening a pathway for water, gas, dirt, insects, snakes, rodents, fire ants, etc. Sometimes the shrinkage results in cracks in the body of the seal itself, again breaking the seal and allowing ingress of water, gas, and other contaminants.

Another problem is that while the volatile content is still present, the putty is essentially a thick liquid. While it may move very slowly, putty does flow under the force of gravity. This slow flow manifests itself in sagging over time, which is another way for the material to separate from the top of the conduit wall and break seal integrity (see Figure 1).

Figure 1

Putty also tends to settle under the crushing weight of cables, opening gaps above the cables. Wire movement causes yet more gaps (see Figure 2).

| Related Content: Duct Seals Prevent Ruinous Water Damage. |

Figure 2

Duct putty seals are often temporary at best.

Duct Putty Performance

The development of gaps and cracks over time is only part of the problem. Another serious consideration is the performance of an otherwise intact duct putty seal that has not yet sagged or cracked. Here the question becomes, how good is a duct putty seal? That question leads to others. How strong is the bond between the putty and conduit wall or cable jacket? How much water head will a duct putty seal hold? How many psi of gas pressure will it resist? The answer to these last two very important questions, unfortunately, is not much.

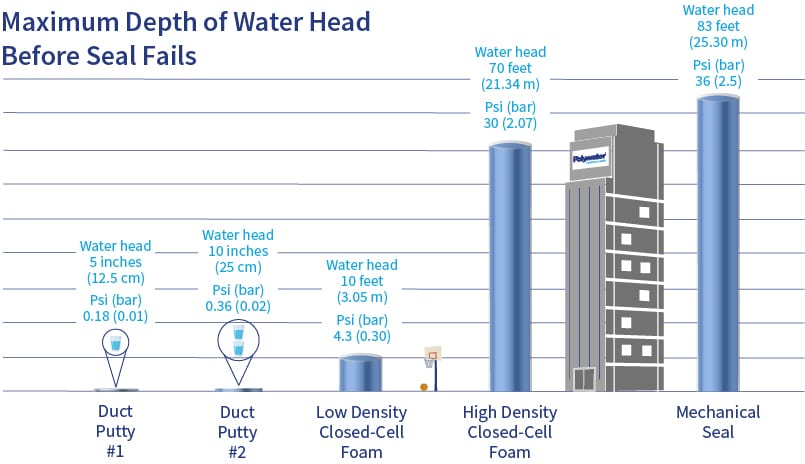

To test seal performance, a one-inch (2.5 cm) plug of putty was fitted into a two-inch (50 mm) PVC conduit. A column of water was then poured over the top of the seal, increasing by one inch (2.5 cm) per day until the seal failed. Two different duct putties were tested and their results are seen in the infographic (figure 3) below:

Figure 3

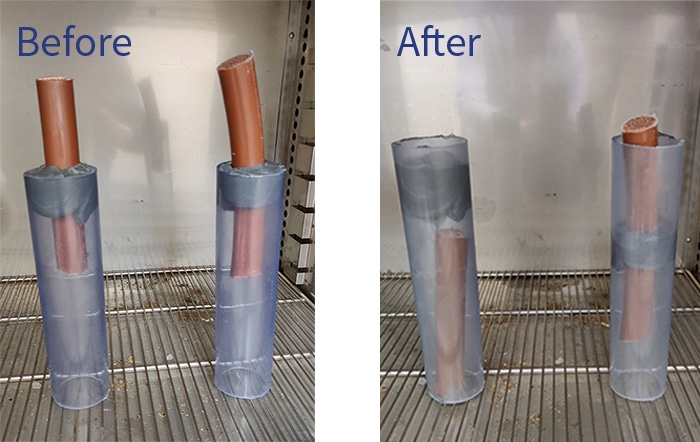

Then the duct putty seals underwent accelerated aging for two weeks at 212°F (100°C). Figure 4 shows the before and after images of this test. Note that the “after” image shows both putties having sagged or shrunk and neither could support the short piece of cable in the duct.

Figure 4

As evident in the “after” image, neither duct putty could hold water once they start to sag or shrink. When combined with the shrinking and sagging factors, the performance numbers for duct putty seals that start out relatively weak to begin with, tend to only go in one direction over time. That direction is down. This should be of significant concern to engineers.

| Related Content: Understanding and Mitigating Manhole Explosions: An Interview with Stuart Hanebuth |

You may see the UL mark and believe this duct putty has been tested for performance, but this is not the true situation. UL Classified duct seals are typically classified under the surface burning characteristics of general use tapes. They have been tested for fire spread and smoke development as part of a surface burning mark. There are no pass/fail criteria, nor any kind of seal testing as part of this classification.

What is at Risk?

When water flows in a conduit through a failed seal, what is at risk? Is it more than just the cable (which is obviously expensive enough)? What else is downstream that can be damaged?

Analysis of the true cost of a cable and conduit installation should extend through the expected lifetime of the system itself, including estimated expenses for repair and replacement. The cost of premature cable failure, compromised electrical apparatus, damaged telecommunications equipment, ruined carpets and flooring, and even stained drywall as a result of failed duct seals should weigh heavily in this analysis. Consider, too, the potential cost of service outages. Is there any legal liability for any resulting damage?

The next step is to assess the source of the threat. If seals fail, will the potential damage be caused by worst-case rainfall, ocean surge, noxious gas buildup, animal infestation, etc.? Can those threats be quantified? How much water head or gas pressure must be resisted for realistic integrity?

What is the Solution?

The solution is to analyze the risks and engineer the system. This includes specifying performance-based sealing materials. Don’t allow the entire system to be threatened by something many view as merely an inconsequential matter: sealing the conduit with a cheap and handy putty.

| Related Content: “Let’s Talk Cabling” Video Podcast: Best Way to Seal OSP Conduit |

Ultimately, the solution is specification of alternate sealing products that meet performance parameters appropriate for the installation, such as closed-cell foams or mechanical seals. Sealants should be sourced from reputable manufacturers offering products developed, tested, and rated specifically for conduits.

After the 2011 tsunami disaster at the Fukushima nuclear plant in Japan, a worldwide reevaluation of flooding hazards and mitigation at all other nuclear sites soon followed. Suffice it to say that today very few of the critically important conduits at nuclear plants are sealed with duct putty. Such seals are engineered for robust performance and long-term integrity. That attention to detail and quality could pay dividends at countless other cable installations worldwide.